In today’s rapidly evolving industrial landscape, the demand for efficient and automated battery assembly line solutions companies has skyrocketed. As the world pivots toward electric vehicles (EVs), energy storage, and smart manufacturing, companies are actively seeking partners who can provide end-to-end battery assembly automation. This is where Parc Robotics stands out — offering advanced, tailor-made solutions that empower businesses to stay ahead in the electric mobility revolution.

Why Battery Assembly Automation is Crucial

Battery assembly is a complex, multi-stage process that includes cell sorting, welding, stacking, module assembly, end-of-line testing, and packaging. These processes demand:

- High precision

- Robust quality control

- Flexible and scalable systems

- Minimal human intervention

Traditional manual setups are not only inefficient but also prone to inconsistencies. As such, battery assembly line solutions companies are revolutionizing how batteries are manufactured — through smart automation, robotics, and integrated control systems.

Key Components of an Automated Battery Assembly Line

A state-of-the-art battery assembly line includes:

- Cell Preparation & Sorting

- Automatic sorting machines categorize cells based on voltage and capacity.

- Ensures only uniform cells enter the next stage.

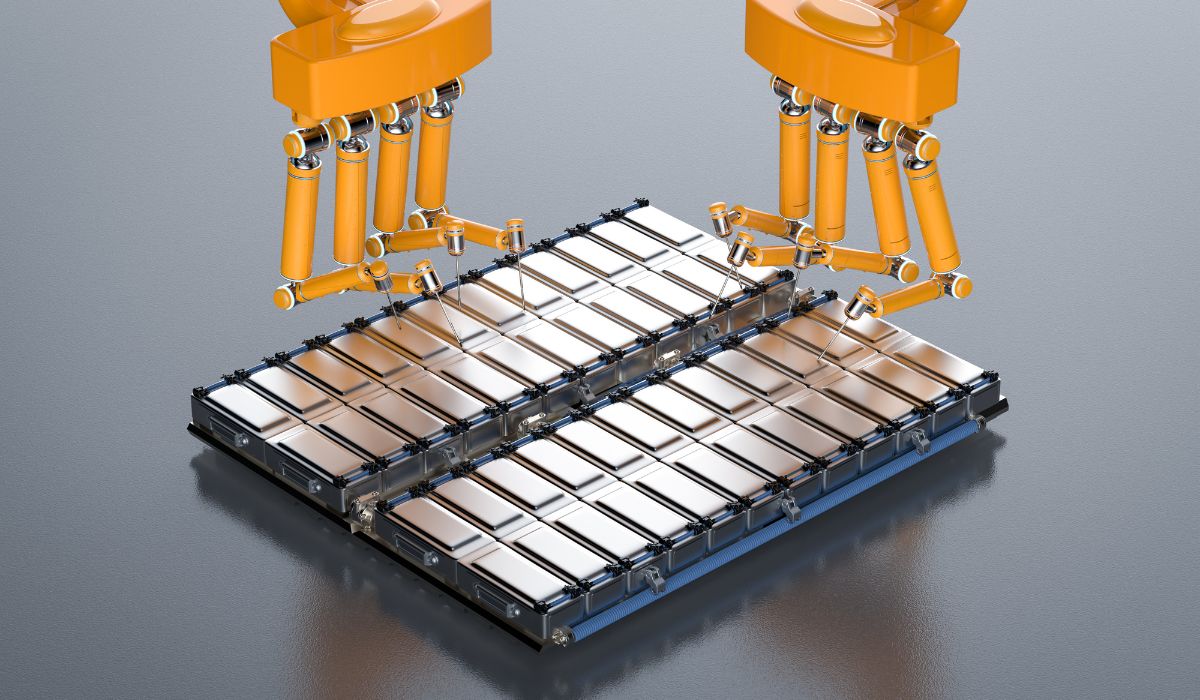

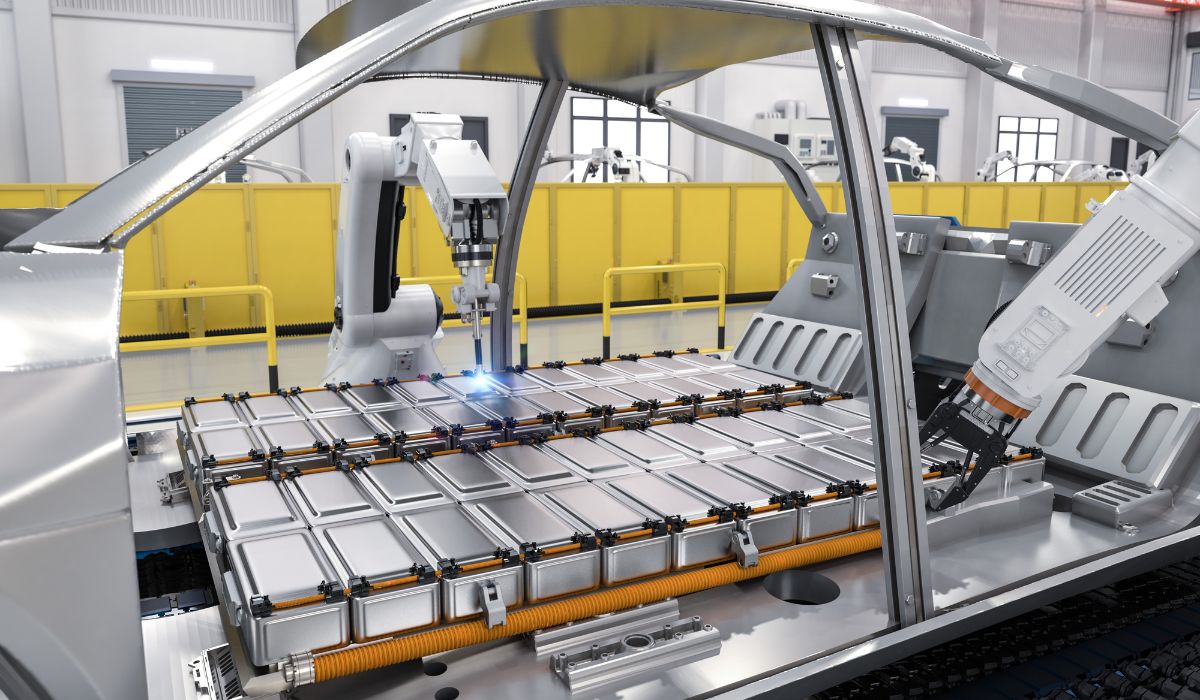

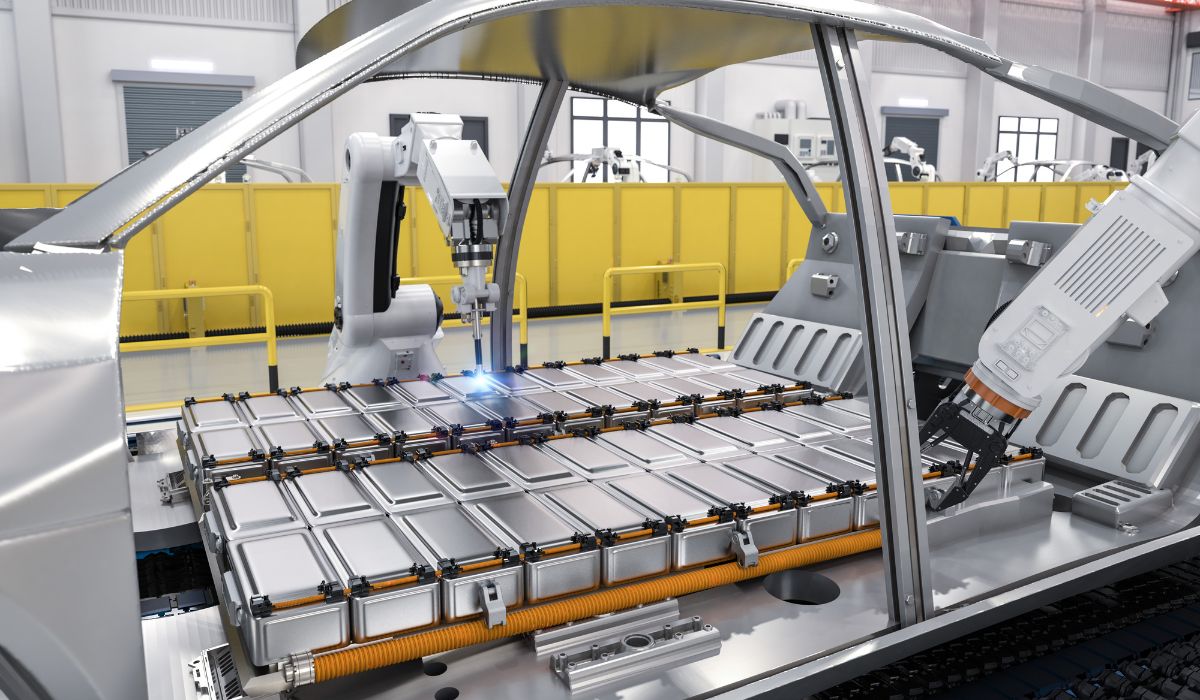

- Welding & Interconnection

- Robotic laser or ultrasonic welding for precision.

- Minimizes heat exposure and improves connection integrity.

- Module & Pack Assembly

- Cells are grouped and assembled into modules or packs.

- Fixtures ensure accuracy in alignment and positioning.

- End-of-Line Testing

- Automated systems check for voltage, capacity, and defects.

- Data logging ensures traceability and quality assurance.

- Packaging & Traceability

- Vision systems verify labeling and barcoding.

- Ready-to-ship battery packs are safely packaged.

Parc Robotics offers customized solutions for each of these phases, ensuring seamless integration and world-class performance.

Why Choose Parc Robotics for Battery Assembly Automation

As a leading battery assembly line solutions company in India, Parc Robotics brings together deep domain expertise in robotics, industrial automation, and manufacturing intelligence.

Here’s what sets us apart:

✅ Tailor-Made Solutions

Every manufacturing facility has unique needs. We design and deploy battery assembly systems that align precisely with your production goals, footprint, and scalability requirements.

✅ EV Industry Expertise

Our systems are engineered with deep knowledge of the EV and energy storage industry. We understand the technical nuances and regulatory standards, ensuring full compliance and reliability.

✅ End-to-End Integration

From cell sorting to end-of-line packaging, we deliver complete turnkey solutions. Our team handles design, engineering, simulation, and deployment — so you don’t have to juggle multiple vendors.

✅ Advanced Fixtures & Tooling

Our high-precision fixtures are designed for durability, ease of use, and repeatable accuracy. Whether it’s for module stacking or spot welding, we ensure robust fixture solutions.

✅ Smart Manufacturing Ready

Our automation systems come with built-in data acquisition and analytics capabilities. This allows for real-time monitoring, preventive maintenance, and smarter decision-making.

Applications Across Industries

While EV battery manufacturing is the most prominent domain, our battery assembly automation systems also cater to:

- Renewable Energy Storage

- Aerospace and Defense Battery Packs

- Industrial Equipment

- Consumer Electronics

With growing adoption of lithium-ion and solid-state batteries, our solutions are already enabling clients to scale up operations while maintaining world-class quality standards.

Client Success Stories

We’ve delivered impactful solutions for top-tier EV OEMs and energy companies. In one case, we helped a Pune-based EV startup reduce battery pack assembly time by 45% using our fully automated robotic line with integrated testing and traceability.

Another client in the renewable sector used our systems to increase throughput by 60%, while maintaining a defect rate below 0.2%.

Future-Ready with Parc Robotics

Whether you’re a startup aiming to build your first pilot line or a large OEM scaling production, we have the tools, experience, and technology to support your journey.