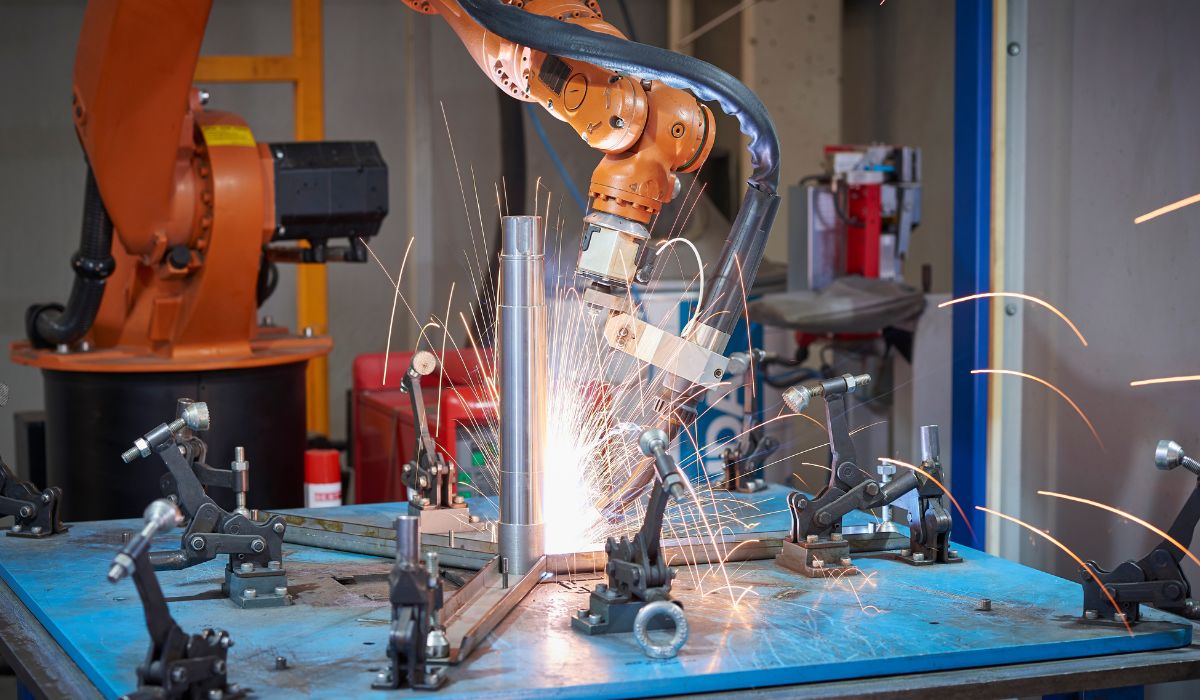

Robotic welding is transforming the manufacturing industry. With the demand for precision, speed, and quality, companies are shifting to automation. One of the key components in robotic welding systems is the welding fixture. These fixtures hold the parts in place during the welding process.

In India, several manufacturers are focusing on producing high-quality robotic welding fixtures. These fixtures are used across industries like automotive, railways, construction, and agriculture. In this blog, we’ll explore what robotic welding fixtures are, why they are important, and who the leading manufacturers in India are — especially how PARC is contributing to this space.

What Are Robotic Welding Fixtures?

Robotic welding fixtures are tools or mechanical devices designed to hold and position components in place during automated welding. These fixtures ensure:

- Consistency in every weld

- Precise alignment of parts

- Reduction in rework

- Faster production cycles

Without a strong fixture, even the best welding robot can fail to deliver quality.

Why Robotic Welding Fixtures Matter

In today’s competitive market, manufacturing speed and accuracy are critical. Robotic welding fixtures bring many advantages:

- Improved Accuracy

Fixtures hold the parts firmly, which reduces human errors and enhances the precision of every weld. - Higher Productivity

With quick loading/unloading systems, robotic fixtures reduce downtime and increase efficiency. - Better Repeatability

Every product that passes through the fixture comes out uniform and consistent. - Worker Safety

Since robots take over manual welding tasks, workers stay safe from heat, fumes, and arc light. - Cost Saving

Reduced rework and faster production mean lower operational costs in the long run.

Applications of Robotic Welding Fixtures Manufacturers in India

India’s industries are fast adopting robotic welding. Here are some of the major sectors:

- Automotive: For welding car frames, exhausts, and other metal parts.

- Railways: Used in the manufacturing of coaches and components.

- Heavy Equipment: In sectors like construction and mining machinery.

- Agriculture Equipment: Tractor bodies and attachments require precision welding.

Key Features of High-Quality Welding Fixtures

If you’re planning to invest in robotic welding fixtures, make sure they have these features:

- Rigid Structure: To avoid any movement during welding.

- Quick Clamping Systems: To speed up the cycle time.

- Accessibility: Designed to allow robots easy access to weld points.

- Customization: Built specifically for your product dimensions.

- Durability: Made from strong materials to withstand long production runs.

Top Robotic Welding Fixtures Manufacturers in India

1. PARC Robotics – Pune, India

It is a fast-growing automation company based in Pune. We specialize in custom robotic welding fixtures, SPMs (Special Purpose Machines), and complete welding automation solutions.

Why Choose PARC Robotics?

- Expert team with deep industry knowledge

- Custom-designed fixtures as per client requirements

- High precision manufacturing

- Cost-effective and timely delivery

- Integration with leading robot brands like ABB, FANUC, and KUKA

At PARC Robotics, we understand that each product is unique. Our fixture solutions are tailor-made to fit the specific welding needs of our clients. Whether it’s a small component or a full automotive chassis, we deliver reliable results every time.

2. Other Notable Players in India

- TATA AutoComp Systems – Known for automotive welding fixtures.

- Godrej Tooling – Offers turnkey automation and welding fixture systems.

- ATS Conveyors – Specializes in fixture-based solutions for body-in-white (BIW).

- Hi-Tech Robotic Systemz – Integrates robotics and fixtures for industrial applications.

However, what makes PARC Robotics stand out is our focus on SMEs (Small and Medium Enterprises). We offer affordable automation to businesses of all sizes.

Choosing the Right Manufacturer: Tips

Before you finalize a robotic welding fixture manufacturer, consider the following:

- Do they offer customization?

- Can they deliver within your timeline?

- Are they using CAD and simulation for design validation?

- Do they provide after-sales support and training?

At PARC Robotics, we check all these boxes.

Future of Robotic Welding Fixtures in India

India’s manufacturing sector is moving towards Industry 4.0. Robotics and automation will be the backbone of this transformation. As demand for quality products grows, robotic welding fixtures will become essential in every factory.

Key trends to watch:

- Smart fixtures with sensors for feedback

- Integration with vision systems

- Use of lightweight materials for faster cycle times

- Modular designs for multiple part variants

Final Thoughts

If you’re looking for reliable robotic welding fixture manufacturers in India, PARC Robotics is your go-to partner. We bring together engineering expertise, modern tools, and custom solutions to deliver high-quality fixtures that enhance your welding process.

Whether you are a startup or an established company, investing in the right fixture will boost your productivity and help you stay competitive.