Introduction – The future of fabrication is robotic

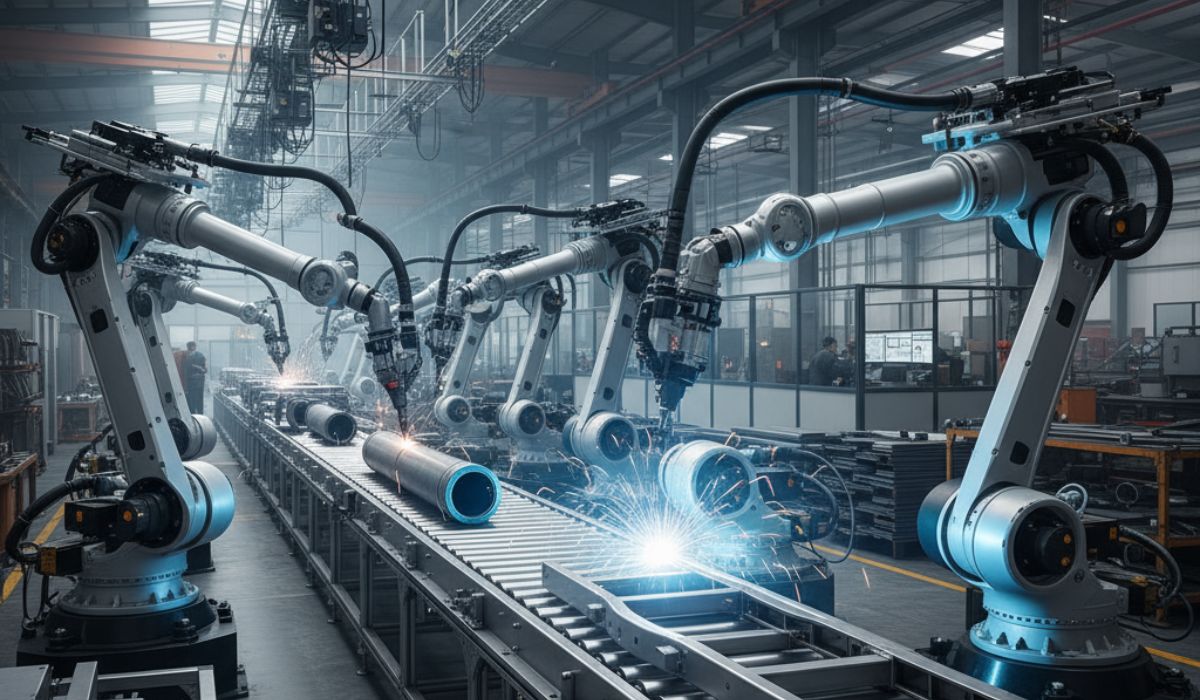

Across metal manufacturing, best robotic welding system for fabrication has moved from a competitive advantage to an operational necessity, driven by the need for precision, throughput, and worker safety under tightening quality and delivery expectations.

Modern fabrication plants use robotic welding automation to stabilize takt times, reduce variability, and ensure consistent weld quality across shifts, materials, and product variants, transforming shop floors into connected, data-aware production environments.

What are robotic welding systems?

Robotic welding systems combine industrial robots, welding power sources, fixturing, safety cells, and software to automate repetitive and semi-complex welding tasks with high repeatability. In MIG (GMAW) automation, wire is continuously fed through a torch with shielding gas to create strong, efficient joints ideal for frames, enclosures, and structural parts.

TIG (GTAW) automation delivers superior control and clean welds for thin-gauge or high-spec materials, often in aerospace and precision assemblies. Spot welding automation uses electrodes and current pulses to fuse sheet metals at precise points, critical for automotive and appliance production.

Each modality is orchestrated through programmable controllers, calibrated TCP (tool center point), and sensor feedback to keep heat input, travel speed, and arc stability within tight process windows.

How robotic welding works in fabrication

- Setup: Parts are located and clamped with precision fixtures or modular tables; weld programs are associated with part numbers and variants, and WPS parameters are validated for materials and thickness.

- Programming: Technicians use teach pendants or offline programming (OLP) to define paths, torch angles, approach/retract moves, and weave patterns, while assigning process parameters like current, voltage, wire feed, and travel speed.

- Welding: The robot executes paths while seam-tracking sensors, arc sensors, or laser vision compensate for joint variation; coordinated motion with positioners or headstocks ensures optimal torch orientation.

- Inspection: Inline monitoring logs current/voltage envelopes, bead geometry, and cycle data; automated checks and camera systems flag anomalies, and part histories are stored for traceability and audits.

Under the hood, control panels manage robot kinematics, I/O, and safety, while the welding power source regulates arc characteristics. Sensors measure torch standoff, joint location, and part presence. Software intelligence handles job scheduling, recipe management, error recovery, and integration with MES/ERP for production visibility.

Top types of robotic welding systems

- Articulated robots: Six or more axes enable complex torch angles and reach into constrained joints, suitable for varied parts and multi-station cells.

- Gantry systems: Overhead rails and carriages cover large envelopes for frames, chassis, beams, and heavy fabrications where payload and reach are critical.

- Collaborative robots (cobots): Force-limited arms enable closer human interaction and faster redeployment, ideal for high-mix/low-volume work and quick changeovers.

- Linear track systems: Robots ride on external axes to extend reach for long welds, large fixtures, and multi-station flow, maintaining accuracy over travel.

Key features of the best robotic welding systems

- High precision and repeatability: Rigid mechanics, encoder feedback, and accurate TCP calibration keep path and torch angle consistent, minimizing porosity and undercut.

- Vision-based seam tracking: Laser or camera systems detect joint location and adapt torch trajectory in real time to handle fit-up variation and part distortion.

- Energy-efficient power control: Inverter-based power sources and process tuning reduce energy draw while maintaining penetration and bead appearance.

- Real-time performance monitoring: Arc-on time, cycle time, first-pass yield, and parameter envelopes are captured, enabling rapid root-cause analysis and continuous improvement.

- Integration with production lines: Standard fieldbuses and digital I/O connect robots to conveyors, PLCs, positioners, and safety systems for synchronized flow and automated part handling.

Benefits of robotic welding automation in fabrication

- Improved productivity and consistency: Robots maintain high duty cycles and uniform torch paths, stabilizing throughput and reducing part-to-part variation.

- Reduced defects and rework: Tight control of travel speed, heat input, and joint tracking cuts spatter, burn-through, lack of fusion, and dimensional distortion.

- Lower labor fatigue and safety risks: Automation removes operators from fume, heat, and repetitive strain exposure while enabling upskilling toward programming and quality roles.

- Faster production with reduced downtime: Standardized fixturing, quick program swaps, and predictive maintenance increase arc-on percentage and reduce stoppages.

- Better material utilization: Accurate heat control and repeatable bead profiles minimize scrap, reduce grinding, and improve downstream fit and finish.

Future trends in welding automation

- AI-based weld quality prediction: Machine learning models correlate sensor signatures with weld defects to adjust parameters before flaws occur, elevating first-pass yield.

- IoT-driven maintenance alerts: Connected power sources, wire feeders, and drive systems report anomalies and wear indicators, enabling planned interventions that limit surprises.

- Data analytics for optimization: Cell-level dashboards surface cycle bottlenecks, arc stability trends, and consumable usage, guiding parameter tuning and fixture improvements.

- Cloud monitoring and remote management: Secure dashboards allow engineers to review KPIs, tweak non-safety parameters, and deploy program updates across sites for standardization.

How to choose the right welding automation system

Selecting the best robotic welding systems for fabrication starts with a structured application assessment. Define annual production volume, takt time targets, and peak demand profiles, then map weld lengths, joint types, and torch orientations to determine whether a single-station cell, indexing table, or multi-robot line is appropriate.

Evaluate part size, weight, and variation: long welds and heavy sections favor gantry or linear track systems, while high-mix/low-volume favors cobots with quick-change tooling. Match materials and thickness to process selection—MIG for robust throughput across steels and aluminum with pulse modes, TIG for thin or cosmetic requirements, and spot welding for sheet assemblies.

Consider budget not only for hardware but also fixturing, safety, offline programming, and commissioning, plus the ongoing costs of wire, gas, tips, nozzles, and preventive maintenance. Finally, prioritize integration readiness: confirm PLC compatibility, fieldbus protocols, floor space, fume extraction, and operator workflow to ensure smooth adoption.

For welding automation systems in existing plants, favor platforms with open integration, scalable external axes, and proven libraries for seam tracking and error handling. Pilot cells use representative parts to validate cycle times and quality against WPS requirements, then scale to multiple stations or lines once the process window is stable.

Implementation best practices

- Design for fixture rigidity and repeatable locating to minimize seam misalignment and reduce reliance on sensor compensation.

- Use offline programming to compress launch timelines, then fine-tune on the floor with accurate TCP calibration and coordinated motion.

- Standardize on consumables and parameter libraries for common joints to simplify training and reduce variation.

- Instrument cells for arc stability, rework codes, and cycle breakdowns; review weekly to drive continuous improvement.

- Establish operator training for torch maintenance, liner changes, tip/nozzle cleaning, and basic program edits to sustain uptime.

Cost, ROI, and scaling

A typical single-robot MIG cell can achieve payback in 12–24 months depending on labor rates, shift patterns, and rework reductions, with faster ROI when welding bottlenecks constrain shipments or overtime.

Soft savings accrue from safety improvements, lower scrap, and reduced grinding, while hard savings appear in higher arc-on time and consistent cycle reduction.

As volume grows, cells scale horizontally by cloning standardized designs, or vertically by adding positioners, external axes, or additional torches to balance flow with upstream forming and downstream machining or coating.

Industry use cases

- Automotive and mobility: High-throughput spot and MIG applications on frames, subframes, and exhaust systems benefit from vision and multi-robot coordination.

- Heavy equipment and construction: Gantry and track systems handle large frames and thick sections with pulse and tandem MIG for deeper penetration and speed.

- General fabrication and job shops: Cobots and flexible fixtures support short runs, rapid changeovers, and late-stage customization without sacrificing quality.

- Aerospace and specialty metals: TIG and hybrid processes deliver cosmetic, low-heat-input welds for thin-gauge and high-spec alloys with stringent documentation.

Our expertise in welding automation

At Parcrobotics, custom robotic welding solutions are engineered to fit real production constraints—part mix, floor space, and target cycle times—so integration is smooth and value shows up from day one.

Our welding automation systems emphasize precision, durable hardware, and maintainability, with vision-based seam tracking, open controls, and analytics-ready data capture to elevate throughput and weld quality.

From application studies and fixture design to programming, training, and lifecycle support, the focus is consistent quality with easy plant integration.

Conclusion – Building the future with smart welding

The best robotic welding systems for fabrication deliver repeatability today and a data foundation for continuous improvement tomorrow, ensuring resilient operations and long-term customer satisfaction.

FAQs

What are robotic welding systems used for in fabrication?

They automate repetitive or complex welding tasks, providing consistent bead geometry, reduced variation, and traceable quality across parts and shifts.

How do robotic welders improve production quality?

Stable travel speed, torch angle, and heat input minimize defects like lack of fusion and spatter, while seam tracking and monitoring keep welds within spec.

Can small fabrication units afford robotic welding automation?

Yes; cobots, modular cells, and phased implementation lower entry costs and allow scaling as demand or product mix evolves.

What is the ROI period for robotic welding systems?

Many projects reach payback in about 12–24 months, influenced by labor costs, utilization, defect reduction, and overtime avoidance.

Are robotic welding systems customizable for different industries?

Absolutely; process selection, fixturing, sensors, and software can be tailored to part geometry, materials, compliance requirements, and production flow for each industry.