Why SPM Manufacturing Topic Matters Now

Let’s get one thing clear from the start — Indian automotive productivity is hitting a ceiling, and the bottleneck is NOT manpower, NOT machines, and NOT raw material.

The real bottleneck is process inconsistency.

Plants are spending crores on expansions, hiring more people, buying new standard machines, and even automating isolated tasks. But output is still choppy, cycle times fluctuate, and OEM audits keep pointing to the same weaknesses:

-

Unstable operations

-

Operator-dependent accuracy

-

High micro-rework

-

Slow line changeover

-

Excessive dependency on skilled manpower

-

Poor traceability in safety-critical components

This is exactly where Special Purpose Machines (SPMs) are taking over the conversation — not as optional upgrades, but as productivity multipliers that Tier suppliers cannot afford to ignore anymore.

And this is why SPM manufacturing companies in India are now shaping the next phase of automotive growth.

Why Standard Machines Can’t Deliver Automotive Productivity Anymore

A standard CNC, VMC, robot, or hydraulic press is designed for “general use.”

But automotive does NOT operate on general use. It operates on:

-

Micro-tolerance

-

Repeatability

-

Consistency across shifts

-

High-volume cycle stability

-

Zero-defect expectations

-

Traceable operations

A standard machine can produce parts.

But it cannot guarantee:

-

Exact fixture alignment

-

Balanced takt time

-

Zero-variation clamping

-

Integrated poka-yoke

-

One-touch operation

-

Interlocking logic to eliminate operator error

-

Real-time production data

That is why MDs and Plant Heads across Pune, Chennai, Gujarat, Haryana, and Hosur are shifting budgets away from standard equipment and into custom SPM solutions.

SPM is not just a machine —

It is a process engineered around your product.

The New Automotive Reality: OEMs Are Pushing Plants Toward Custom Automation

OEM requirements have changed drastically in the last 5–7 years.

Old expectations:

-

Parts delivered on time

-

Minimal rejection

-

Basic documentation

Current expectations:

-

Measurable, repeatable, logged operations

-

Fixture-level stability

-

Traceable torque, weld, press-fit and fastening values

-

In-line error-proofing

-

Robotic or automated consistency

-

Zero deviation in safety-critical assemblies

-

PPM targets that require automation-level accuracy

You simply cannot meet these expectations with:

-

Manual workstations

-

Standard machinery

-

Operator-led operations

OEMs don’t just want parts.

They want a controlled, documented, traceable process behind every part.

SPMs deliver exactly that.

What Makes SPMs Critical for Productivity (Not Just Quality)

Indian automotive output is rising, but cycle-time pressure is rising even faster.

Manufacturers now face:

-

Higher volumes

-

Shorter model life cycles

-

More SKUs

-

Complex part geometries

-

Stricter tolerance bands

-

More safety-critical subassemblies

SPM solves these productivity challenges because it is engineered for:

1. Faster cycle time without sacrificing accuracy

Every movement is engineered:

-

Custom fixture

-

Custom mechanism

-

Custom tooling

-

Custom automation sequence

You get consistent takt, every shift, every day.

2. Zero operator dependence

SPM removes human variability through:

-

Interlocks

-

Sensors

-

Guided operation

-

Auto-clamping

-

Load/unload discipline

-

Error-proofing logic

This becomes a huge advantage during manpower shortages or absenteeism.

3. Better layout optimization

SPMs require less space compared to multiple standard machines performing the same task.

4. Integration with robots, conveyors, torque tools, weld guns

This is where top spm manufacturing companies in India add real value —

not with the machine alone, but with the system approach.

5. Monitored and traceable operations

With:

-

Load sensors

-

Laser detection

-

Vision cameras

-

PLC logs

-

SCADA reporting

-

Barcode/RFID mapping

-

Real-time dashboards

OEM audits become significantly easier.

6. Reduced rework & higher first-pass yield

When your operation is fixed and controlled, output becomes predictable — which is EXACTLY what MDs want.

Why Tier-1 & Tier-2 CEOs Are Increasing SPM Budgets

For automotive suppliers, the biggest threat is not competition —

it’s process instability that OEMs can’t rely on.

Top decision-makers invest in SPMs because:

✔ They secure OEM trust

OEMs prefer suppliers who operate on controlled, automated sequences.

✔ They protect margins

Lower rework → better PPM → stronger negotiation power.

✔ They reduce human skill dependency

A major long-term risk is skilled labor shortage.

SPM eliminates that dependency.

✔ They support future EV requirements

EV components require:

-

Micro-fitting

-

Controlled press operations

-

Zero-defect fastening

-

Robotic pick-place

-

High-precision assembly

SPMs are built exactly for such operations.

✔ They differentiate the company in vendor selection

When a supplier shows SPM capability, OEMs see:

-

Stability

-

Process maturity

-

Reliability

-

Long-term consistency

This can literally decide who gets the next long-term order.

How SPMs Transform Different Automotive Segments

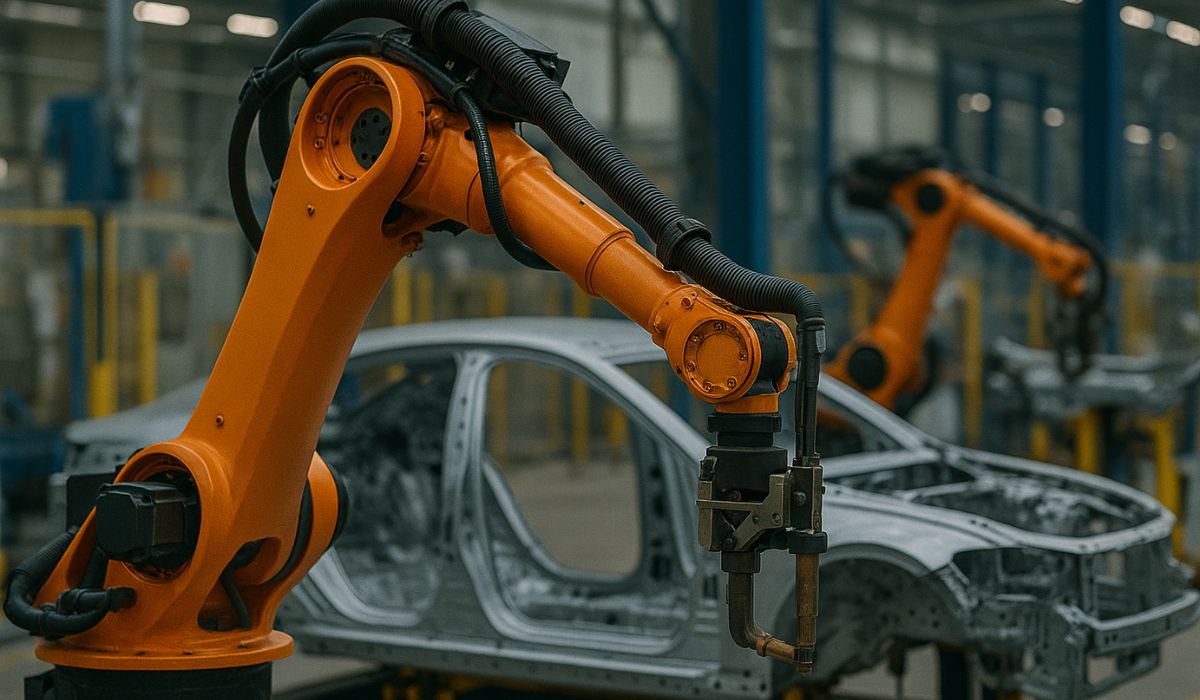

1. Automotive OEMs

Need SPMs for:

-

BIW subassemblies

-

Chassis joining

-

Door hemming

-

Critical fastening

-

Welding stations

-

Vision inspection

2. Tier-1 Suppliers

Use SPMs for:

-

Seat frames

-

IP carriers

-

Exhaust components

-

Axle subassemblies

-

HVAC units

3. Tier-2 Suppliers

Use SPMs for:

-

Brackets

-

Small weldments

-

Press-fit operations

-

Machining sequences

4. Fabrication Workshops

SPMs help them move from “local fabricator” to OEM-approved vendor.

5. EV Battery Plants

SPMs are used for:

-

Cell sorting

-

Module welding

-

Cooling plate assembly

-

Busbar fastening

-

Laser inspection

This segment has the highest growth, and SPMs are becoming the backbone of EV assembly.

Why Indian Manufacturers Prefer Indian SPM Companies Over Imported Solutions

MDs now prefer Indian SPM manufacturers because:

-

Faster service support

-

Local engineering understanding

-

Lower maintenance cost

-

Affordable spares

-

Custom design for Indian conditions

-

Shorter lead times

-

Local PLC support

-

Zero communication barriers

Imported SPMs often fail due to:

-

No local spare availability

-

Poor documentation

-

No real-time support

-

High modification cost

-

Lack of flexibility for Indian volumes

Indian SPM companies design for:

-

Indian manpower

-

Indian layouts

-

Indian shift patterns

-

Indian maintenance conditions

This makes them more reliable and more adaptable.

What MDs Should Evaluate Before Choosing an SPM Partner

If you’re selecting from SPM manufacturing companies in India, these are the non-negotiables:

1. Fixture engineering capability

(Weak fixture = failed SPM, no matter how expensive the machine is.)

2. Simulation expertise

To ensure cycle time stability.

3. In-house design team

Mechanical + electrical + controls + welding experts.

4. Safety interlocks & logic design

Absolutely mandatory for OEM compliance.

5. Scalability

The SPM must be upgradeable later.

6. Documentation & traceability

OEMs will demand proper documents.

7. Field support

If service is slow, the machine becomes a liability.

The Business Reality MDs Need to Understand

SPM is NOT an expense.

SPM is protection against business risk, specifically:

-

Rework risk

-

Skilled labor risk

-

Audit failure risk

-

Delivery delay risk

-

Cost escalation risk

-

Competitor automation risk

Every successful Tier-1 CEO knows:

“You don’t lose orders because your price is higher.

You lose orders because your process is less stable.”

And SPMs stabilize your entire value chain.

Final Thought

Indian automotive growth is entering a phase where efficiency is no longer optional.

OEMs aren’t impressed by factories with big machines anymore.

They reward suppliers who can demonstrate:

-

Repeatability

-

Stability

-

Traceability

-

Predictable output

-

Zero-defect approach

SPMs are not “special” machines anymore.

They are becoming the standard baseline for any supplier who wants to survive the next decade of automotive transformation.

If you’re aiming for long-term OEM trust, you cannot rely on manual or general-purpose machines.

SPMs are how Indian manufacturers will reach global productivity benchmarks.

FAQs “SPM Manufacturing for Indian Automotive Productivity”

1. Why are Indian automotive companies shifting aggressively toward SPM automation?

Because manual, general-purpose machines cannot meet the cycle time discipline, repeatability, and output stability required by OEMs today. SPMs remove operator dependency and convert critical operations into controlled, repeatable processes, which OEMs reward with better ratings and stable vendor positions.

2. How does SPM manufacturing directly impact plant productivity?

SPMs eliminate variation in cycle time, reduce human fatigue, and stabilize throughput. This leads to predictable daily output, fewer bottlenecks, and significantly lower downtime. Plants that rely on standard machines or manual setups face inconsistent hourly production.

3. Are SPMs only suitable for large OEMs?

No. Tier-1 suppliers, Tier-2 fabrication units, and even specialised component manufacturers benefit faster. In fact, smaller suppliers see the highest ROI because SPMs help them meet OEM timelines without increasing manpower cost.

4. What is the ROI timeline for investing in an SPM?

Most Indian plants recover the investment within 8–18 months, depending on part complexity and production volume. Savings come from improvements in:

-

Cycle-time consistency

-

Reduced rework and scrap

-

Lower manpower dependency

-

Higher dispatch reliability

5. What happens if a company delays SPM adoption?

They lose negotiation power. OEMs prefer suppliers who can maintain zero-variation processes. Plants still dependent on manual setups quickly become “secondary vendors” and face continuous price pressure from automated competitors.

6. How important is fixture design in an SPM?

Critical. An SPM is only as effective as its fixture engineering. Poor clamping, bad ergonomics, or misaligned guides can destroy cycle time and accuracy. The robot or mechanism is never the problem—bad fixturing removes the ROI.

7. Are SPMs relevant for EV battery manufacturing?

Absolutely. Battery pack assembly, cell welding, busbar installation, and enclosure torquing require high precision, zero human error, and strict safety standards. EV plants rely heavily on SPMs to maintain consistent assembly quality.