Engineering-Driven Robotic Automation for Two Wheeler Frame Production

Two wheeler frame automation requires more than standard welding robotics—it demands an integrated approach to part positioning, thermal management, and process control. Parc Robotics designs and deploys fully engineered robotic welding systems specifically for motorcycle frames, scooter underbodies, and tubular chassis structures. Our methodology combines application-specific robotics, precision fixture engineering, and adaptive welding processes to deliver repeatable, high-integrity welds at production volumes.

Why Two Wheeler Frame Automation Is Critical for Structural Integrity

Two wheeler frames are safety-rated structural components. Every weld directly influences vehicle stability, fatigue life, and crash performance. Manual welding introduces unacceptable variability in penetration depth, heat input, and bead profile—leading to dimensional distortion and hidden defects that compromise frame integrity.

Automation eliminates this variability. Robotic systems maintain consistent torch angle, travel speed, and wire feed parameters across every weld cycle. For thin-wall tubular frames—typically 1.5 mm to 3 mm wall thickness—precise heat control is essential. Robotic pulse MIG welding allows controlled heat input, reducing distortion while preserving parent material strength.

The precision manufacturing capability of automated systems extends beyond welding. Integrated clamping sequences hold tight tolerances throughout the process, maintaining critical locating points for downstream assembly. This level of repeatability is unachievable with manual tack-and-weld methods at high production volumes.

System Architecture: Integrated Robotic Welding Cell for Frame Automation

A complete two wheeler frame automation system comprises four interdependent subsystems engineered for continuous production:

1. Robotic Manipulator

Six-axis articulated robot with payload capacity matched to the welding torch and dressing unit. For motorcycle frame automation, reach and wrist flexibility must accommodate complex tubular geometries without re-gripping. We specify robots with through-arm dressing and collision detection for uninterrupted operation.

2. Precision Fixturing and Clamping Systems

The fixture is the foundation of repeatability in two wheeler frame automation. Dual-station rotary or shuttle-type positioners allow load/unload during welding. Fixtures incorporate pneumatic or hydraulic clamps with position monitoring. Locating points are hardened and replaceable. Thermal expansion characteristics are calculated into clamp placement to avoid constraint during welding.

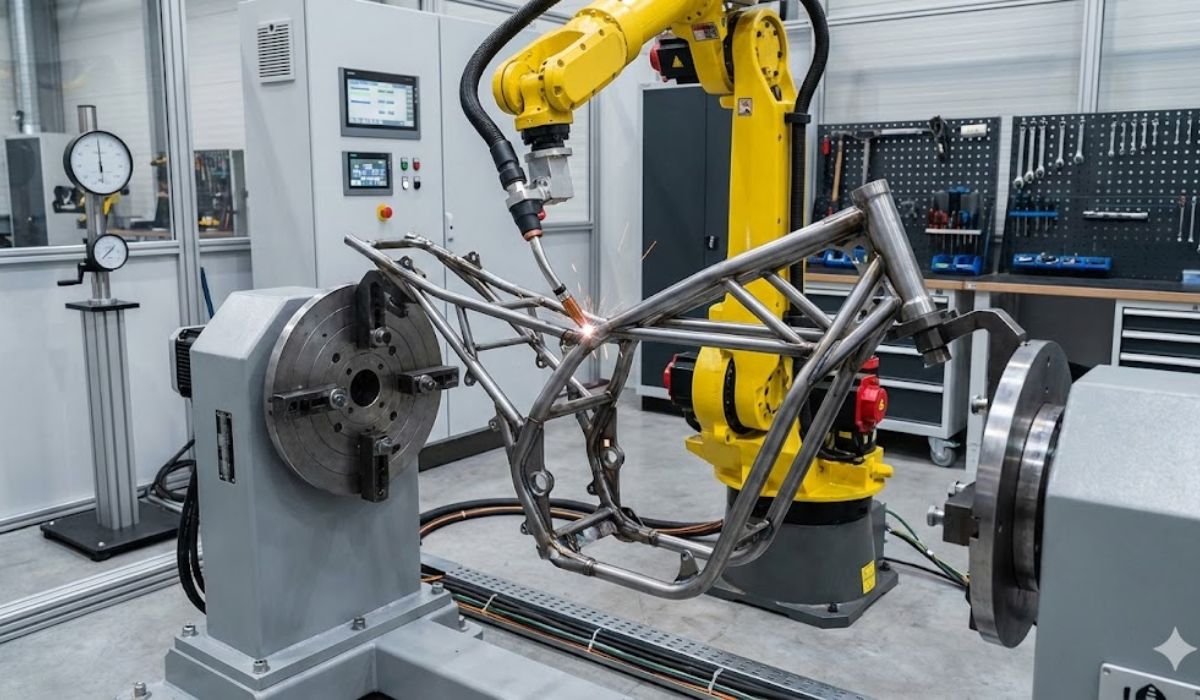

3. Coordinated Positioning Equipment

External axes—headstock-tailstock or turntable configurations—manipulate the weldment to maintain optimal torch orientation. Synchronized motion between robot and positioner enables downhand welding wherever possible, improving deposition rates and bead appearance while reducing operator intervention.

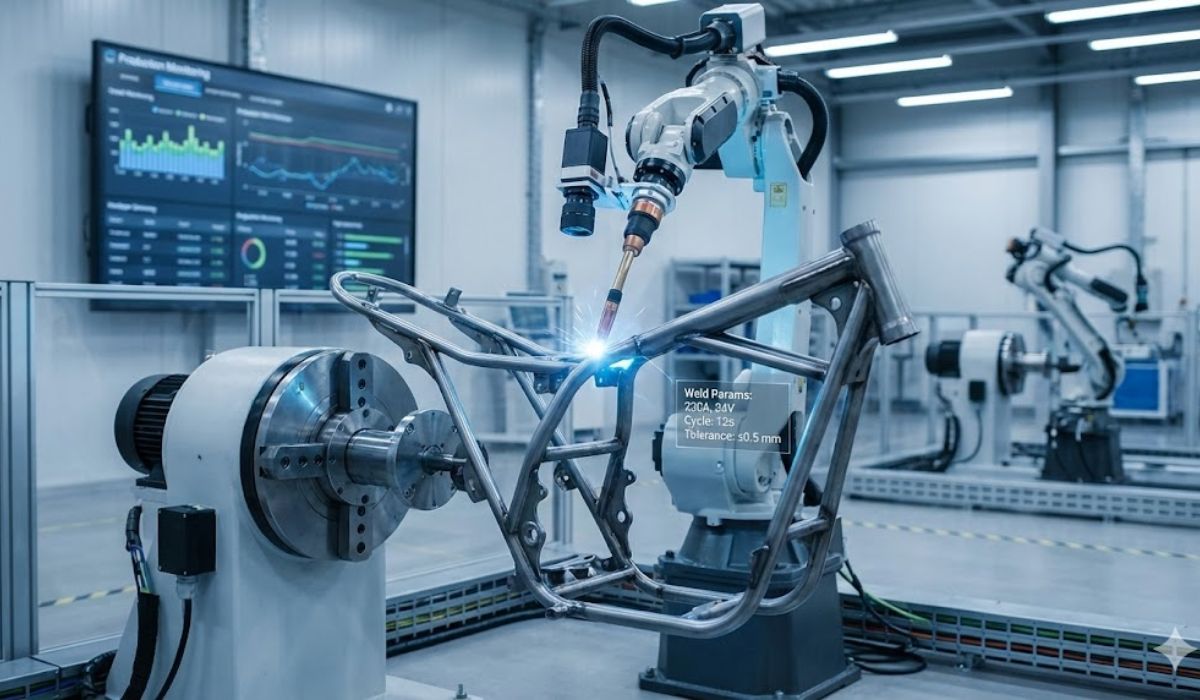

4. In-Process Inspection and Monitoring

Integrated seam tracking and through-arc sensing adjust torch path in real time to compensate for component tolerances or fit-up variation. Post-weld vision inspection checks for critical weld presence and geometric conformity, ensuring every frame meets specification before leaving the cell.

How Robotic Welding Enables Precision Manufacturing in Two Wheeler Production

Precision manufacturing in two wheeler frame fabrication demands control across multiple variables simultaneously. Robotic automation achieves this through:

Dimensional Control: Parts held to ±0.5 mm on critical locating points ensures consistent fit-up in subsequent assembly operations without grinding or shimming.

Thermal Management: Programmed weld sequences balance heat input across the structure, preventing the distortion patterns common in manual welding of thin-wall tubing.

Process Documentation: Every weld parameter is logged and traceable, supporting quality certifications and customer audits with objective data.

Repeatability: The same weld quality at 8 AM on Monday as at 4 PM on Friday—independently of operator skill variation or shift changes.

A well-engineered two wheeler frame automation system ensures structural consistency across high-volume motorcycle manufacturing lines, directly impacting downstream assembly efficiency and final product quality.

Measurable Benefits: Realistic Industrial Metrics for Frame Automation

Implementing robotic two wheeler frame welding delivers quantifiable improvements across production metrics:

Cycle Time Reduction: 30–50 percent reduction compared to manual welding, depending on joint complexity and part handling efficiency. Dual-station fixturing eliminates torch-off time completely.

Rejection Rate Reduction: Scrap and rework typically fall from 5–8 percent in manual operations to below 1 percent in automated cells. Consistent parameter control eliminates common defects like cold lap, undercut, and incomplete fusion.

Dimensional Consistency: Part-to-part variation reduces to ±0.5 mm on critical locating points, ensuring downstream assembly fit-up without manual correction.

Consumables Savings: Precise wire feed and gas control reduce over-welding. Typical wire savings of 10–15 percent are achieved through consistent bead sizing alone.

ROI Drivers: Primary ROI levers are direct labor replacement, reduced rework cost, and increased throughput without floor space expansion. Typical payback periods range from 18 to 36 months based on shift patterns and production volumes—validated across multiple installations for Indian and global two wheeler manufacturers.

Common Automation Mistakes in Two Wheeler Frame Welding

Inadequate Fixture Rigidity: Frames spring during welding if clamping does not restrain all degrees of freedom. Fixtures must resist both clamping forces and thermal expansion without measurable flex.

Ignoring Part Tolerances: Stamped or bent tube components vary within acceptable limits. Without adaptive welding or seam tracking, robots weld in the same programmed path regardless of part position—resulting in missed joints or burn-through.

Poor Weld Sequence Planning: Robotic welding follows programmed sequences rigidly. If the sequence induces distortion by welding one side fully before the opposite side, frames twist. Sequence must balance heat input across the entire structure.

Underestimating Cycle Time Components: Part loading, clamp actuation, torch cleaning, and repositioning all add to total cycle time. Simulation must account for all non-welding activities to set realistic production targets.

Our Methodology: From Process Study to Commissioning

1. Process Study and Joint Analysis

We begin by analyzing your frame drawings, material specifications, and weld requirements. Joint access, tube wall thickness, and required penetration levels determine welding process selection—typically pulsed MIG for thin-wall tubes to control heat input.

2. Conceptual Design and Simulation

Offline programming software simulates robot motion, positioner synchronization, and torch reach. Cycle time estimates are validated, and collision risks eliminated before hardware build. Weld sequence is optimized specifically for distortion control.

3. Fixture Engineering and Fabrication

Fixtures are designed with modularity where possible, allowing future adaptation for new frame models. Clamping points, locating pins, and rest pads are precision-machined from tool steel. Thermal management features prevent heat buildup in locating surfaces.

4. System Integration and Programming

Robots, positioners, and safety systems are integrated and fully programmed. Weld parameters are established through sample welding and destructive testing. Torch angles and weave patterns are refined for bead appearance and penetration.

5. Validation and Commissioning

On-site installation includes runoff with your production parts. Weld integrity is verified through macro-section analysis and tensile testing where specified. Operator training covers system operation, basic programming, and routine maintenance procedures.

Future Trends in Two Wheeler Frame Automation

Adaptive Welding Control: Next-generation systems monitor weld pool behavior in real time and adjust parameters dynamically. This compensates for minor joint fit-up variations without stopping production—essential for precision manufacturing environments.

Integrated Vision for Seam Finding: Three-dimensional vision systems locate joints even when part position varies, enabling robotic welding of unpresented frames without dedicated fixturing for every model.

IoT-Based Process Monitoring: Welding data—current, voltage, wire feed speed, gas flow—is streamed to cloud platforms. Anomaly detection alerts maintenance to developing issues before they cause defects.

Collaborative Robotics for Low-Volume Mix: High-mix, low-volume production benefits from collaborative robots that work alongside operators for quick changeover between frame models.

Strategic Value of Precision Manufacturing

Two wheeler frame automation is not merely a labor substitution—it is a quality enablement strategy. Consistent weld integrity reduces warranty risk. Repeatable dimensional accuracy simplifies assembly. Documented process data supports quality certifications and customer audits.

Parc Robotics approaches each installation as an engineering partnership. We do not supply generic welding cells; we engineer systems matched to your frame geometry, production volume, and quality requirements. Our experience spans applications from high-volume scooter underbody lines to flexible cells for multiple motorcycle frame variants.

Feasibility Study and Consultation

If you are evaluating automation for two wheeler frame production, we offer a structured feasibility study. A preliminary process audit can identify whether automation will deliver measurable gains in your current production environment. Our engineering team reviews your current process, part drawings, and production targets to define system requirements and projected ROI. Contact us to schedule a technical discussion.

Frequently Asked Questions

1. What welding process is recommended for thin-wall motorcycle frames in two wheeler frame automation?

Pulsed MIG welding is preferred for thin-wall tubular frames in the 1.5 mm to 3 mm range. It provides stable arc control, reduced spatter, and lower heat input compared to conventional spray transfer—minimizing distortion while achieving full penetration for structural integrity.

2. How does fixture design affect weld quality in automated frame production?

Fixtures must locate the frame precisely and restrain it against welding distortion. Poor fixture design allows movement during welding, leading to dimensional variation and residual stress. Hardened locating points, thermal relief features, and positive clamping with position monitoring are essential for precision manufacturing.

3. Can a robotic two wheeler chassis welding system handle multiple frame models in one cell?

Yes, with appropriate fixturing and programming. Quick-change tooling or multi-station turntables allow different frame models to be welded in sequence. Vision-assisted seam finding reduces changeover time by accommodating minor part variations without mechanical re-fixturing.

4. What cycle time can be expected for motorcycle frame welding with robotic automation?

Cycle time depends on joint count and part complexity. A typical scooter underbody or motorcycle main frame requires 4 to 8 minutes of arc-on time. Dual-station cells achieve effective cycle times of 2 to 4 minutes per part by enabling load and unload during welding operations.

5. How is weld quality verified in automated two wheeler frame production?

In-process monitoring tracks welding parameters for each weld seam. Post-weld inspection may include vision systems for bead presence and geometry. Destructive testing of sample parts validates mechanical properties periodically. Some installations integrate non-destructive testing methods for critical joints requiring full traceability.