In CNC machining, fixture design is not a support function. It is a process-defining element. Tool accuracy, surface finish, cycle time stability, and even tool life are directly influenced by how consistently a component is located and clamped.

Hydraulic fixtures exist because mechanical and manual clamping systems fail to meet modern production requirements once volumes increase, tolerances tighten, and automation is introduced. This article explains how hydraulic fixtures actually work in real machining environments, what design logic engineers should evaluate, and where they deliver measurable advantages over conventional fixturing.

This is written for design and manufacturing engineers, not buyers looking for brochures.

Why Manual and Mechanical Fixtures Break Down in CNC Production

In low-volume or prototype machining, manual fixtures are acceptable. In production environments, they become a liability.

Common issues observed on shop floors:

-

Operator-dependent clamping force

-

Inconsistent part seating due to uneven tightening

-

Micro-movement during heavy cutting

-

Increased setup and changeover time

-

Difficulty in synchronizing clamping with CNC cycles

Even well-designed mechanical fixtures suffer from force variation. Torque applied by an operator does not translate into consistent clamping force, especially across shifts.

Hydraulic fixtures solve this problem by decoupling clamping force from human input.

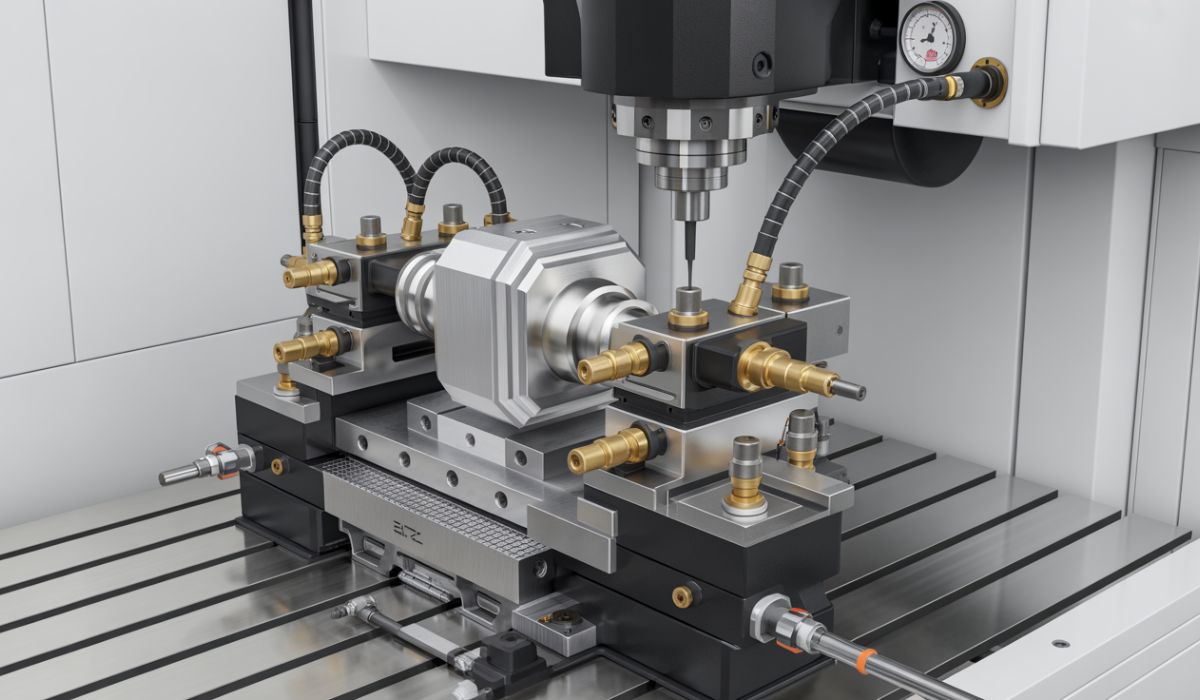

What a Hydraulic Fixture Actually Does (Beyond the Basic Definition)

At a system level, a hydraulic fixture provides:

-

Controlled and repeatable clamping force

-

Simultaneous clamping across multiple points

-

Predictable part location under load

-

Integration with CNC and automation systems

The critical advantage is not “hydraulics” as a concept.

The advantage is force consistency under dynamic machining conditions.

When clamping force is predictable:

-

Part deformation can be controlled

-

Datum repeatability improves

-

Machining parameters can be pushed safely

-

Tool wear becomes more predictable

This is why hydraulic fixtures are common in automotive, EV, aerospace, and high-volume industrial machining.

Core Design Principles of Hydraulic Fixtures for CNC Machining

A hydraulic fixture is only as good as its design logic. Poorly designed hydraulic fixtures fail just as badly as poor manual fixtures.

1. Location Before Clamping

Hydraulics do not fix bad location design.

A correct fixture follows the rule:

Locate first, clamp second, machine last

-

Primary, secondary, and tertiary locators must fully constrain the part

-

Hydraulic clamps should only apply force, not locate geometry

-

Over-constraining must be avoided to prevent distortion

Engineers often mistake high clamping force for stability. In reality, force direction and locator strategy matter more than force magnitude.

2. Clamping Force Calculation (Not Guesswork)

Hydraulic fixtures allow force control — but only if it is calculated.

Force must account for:

-

Cutting forces (directional, not scalar)

-

Tool engagement and depth of cut

-

Part material and wall thickness

-

Safety factor without deformation risk

Excessive force:

-

Distorts thin-walled components

-

Causes dimensional variation after unclamping

Insufficient force:

-

Allows micro-movement

-

Leads to chatter and surface finish issues

Proper hydraulic fixture design balances minimum required force with maximum stability.

3. Hydraulic Circuit Reliability

Fixture reliability is not about clamps alone. It depends on the hydraulic circuit design.

Key engineering considerations:

-

Leak-proof fittings and hose routing

-

Pressure loss across the circuit

-

Sequence control for clamp actuation

-

Fail-safe logic in case of pressure drop

In production environments, even minor leaks result in:

-

Clamp force variation

-

Machine downtime

-

Safety risk during machining

This is why industrial hydraulic fixtures are designed as systems, not assemblies.

Hydraulic Fixtures for Machining Centers

Machining centers introduce additional complexity:

-

Multi-axis cutting forces

-

Higher spindle speeds

-

Multiple operations in one setup

Hydraulic fixtures are particularly effective here because they:

-

Maintain consistent force during axis changes

-

Enable multi-point simultaneous clamping

-

Reduce part re-location between operations

For horizontal machining centers (HMCs), hydraulic fixtures allow:

-

Stable machining on multiple faces

-

Faster pallet changeovers

-

Better repeatability across batches

For vertical machining centers (VMCs), they improve:

-

Tool access

-

Chip clearance

-

Setup repeatability

Repeatability and Accuracy: The Real Advantage

Most engineers underestimate how much variation is introduced by manual clamping.

Hydraulic fixtures improve:

-

Datum repeatability

-

Dimensional consistency across batches

-

Cpk values in critical operations

Because clamping force is controlled, engineers can:

-

Standardize machining parameters

-

Reduce inspection variation

-

Minimize post-machining corrections

In automated or semi-automated lines, hydraulic fixtures become essential. Manual clamping simply cannot be synchronized reliably with machine logic.

Custom vs Standard Hydraulic Fixtures

Standard fixtures work when:

-

Part geometry is simple

-

Volumes are moderate

-

Tolerances are forgiving

Custom hydraulic fixtures are required when:

-

Geometry is complex or asymmetric

-

Thin-walled components are involved

-

Multiple operations are combined

-

Automation or robotic loading is planned

Custom design allows:

-

Optimized locator placement

-

Controlled force distribution

-

Integration with sensors and interlocks

-

Compatibility with automation systems

This is where engineering-driven fixture manufacturers differentiate themselves from catalog suppliers.

Integration with CNC and Automation Systems

Modern hydraulic fixtures are rarely standalone.

They are often integrated with:

-

CNC machine PLCs

-

Robotic loading systems

-

Automated assembly lines

-

Error-proofing and safety logic

Integration benefits:

-

Machine cannot cycle unless clamps are confirmed

-

Clamping and unclamping are synchronized with CNC programs

-

Reduced operator dependency

-

Improved safety compliance

For manufacturers already using robotic systems or SPMs, hydraulic fixtures become part of the overall automation architecture, not just a tooling element.

Industries Where Hydraulic Fixtures Are Technically Justified

Hydraulic fixturing is most effective where process stability matters more than fixture cost:

-

Automotive and EV components

-

Aerospace machining

-

Heavy engineering

-

High-volume industrial manufacturing

In these environments, fixture reliability directly affects:

-

Throughput

-

Scrap rate

-

Machine utilization

-

Quality consistency

Common Engineering Mistakes in Hydraulic Fixture Design

Even experienced teams make these mistakes:

-

Using excessive clamping force “for safety”

-

Treating clamps as locators

-

Ignoring part deformation after unclamping

-

Poor hydraulic circuit layout

-

Designing fixtures without considering automation compatibility

Hydraulic fixtures demand engineering discipline, not just hydraulic knowledge.

FAQs

What is the main advantage of hydraulic fixtures in CNC machining?

Consistent and repeatable clamping force, which directly improves dimensional accuracy and process stability.

Are hydraulic fixtures suitable for thin-walled components?

Yes, if clamping force is calculated correctly and force distribution is controlled to avoid distortion.

How do hydraulic fixtures improve repeatability?

By eliminating operator-dependent force variation and applying uniform clamping across cycles.

Can hydraulic fixtures be integrated with automation systems?

Yes. They are commonly integrated with CNC PLCs, robotic loading systems, and automated lines.

Are custom hydraulic fixtures better than standard fixtures?

For complex geometry, tight tolerances, or automation, custom fixtures provide better control and reliability.

Final Thought

Hydraulic fixtures are not a luxury upgrade.

They are a process control tool.

For engineers responsible for accuracy, repeatability, and scalable production, hydraulic fixturing is often the difference between a process that works occasionally and one that works every shift, every batch.

When designed and integrated correctly, hydraulic fixtures enable CNC machining to operate closer to its true capability — not its theoretical limits.