In today’s industrial landscape, high-performance, reliable, and automated production systems are essential. At the heart of many of these systems are hydraulic fixtures and machines — tools that provide the clamping force, precision, and dependability needed to ensure quality and productivity.

As a trusted name among hydraulic fixtures and machine manufacturers, Parc Robotics delivers cutting-edge, application-specific solutions to industries such as automotive, aerospace, defense, and heavy engineering. We engineer each fixture and machine with strength, control, and adaptability in mind.

What Are Hydraulic Fixtures?

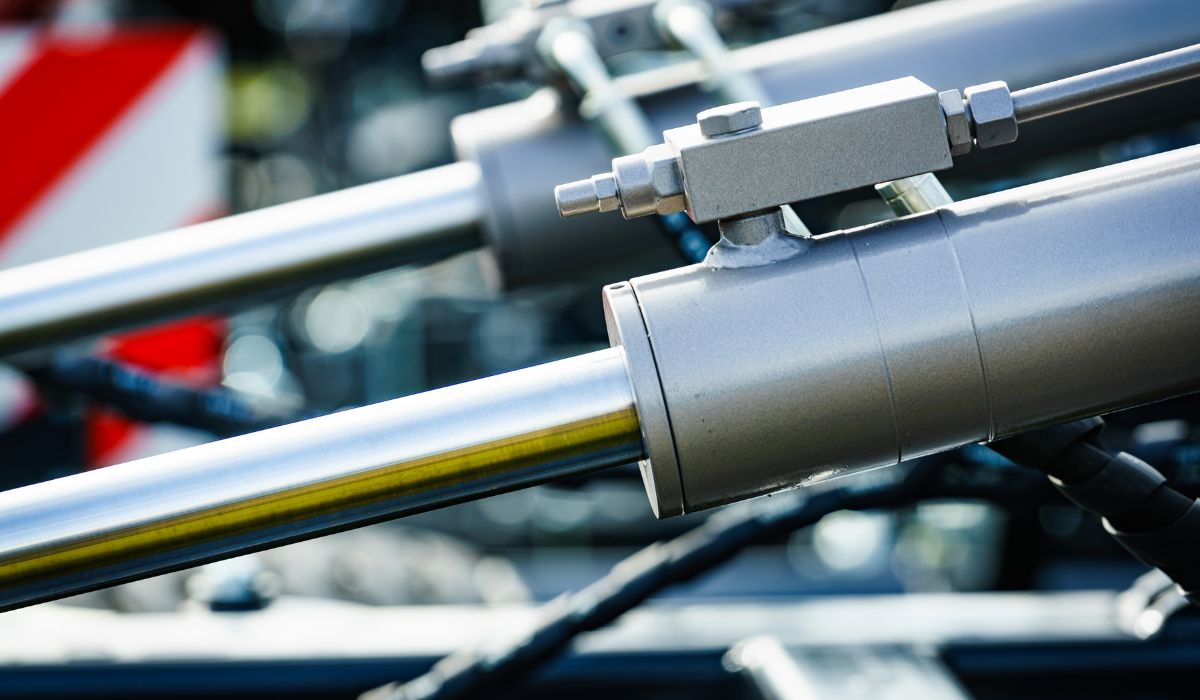

Hydraulic fixtures are specialized devices used to hold workpieces securely during operations like machining, welding, testing, or assembly. They outperform manual and pneumatic fixtures by offering higher clamping force, better repeatability, and seamless integration with automation systems.

Benefits of hydraulic fixtures include:

- Consistent clamping force to reduce variation and improve quality

- Shorter cycle times and higher productivity

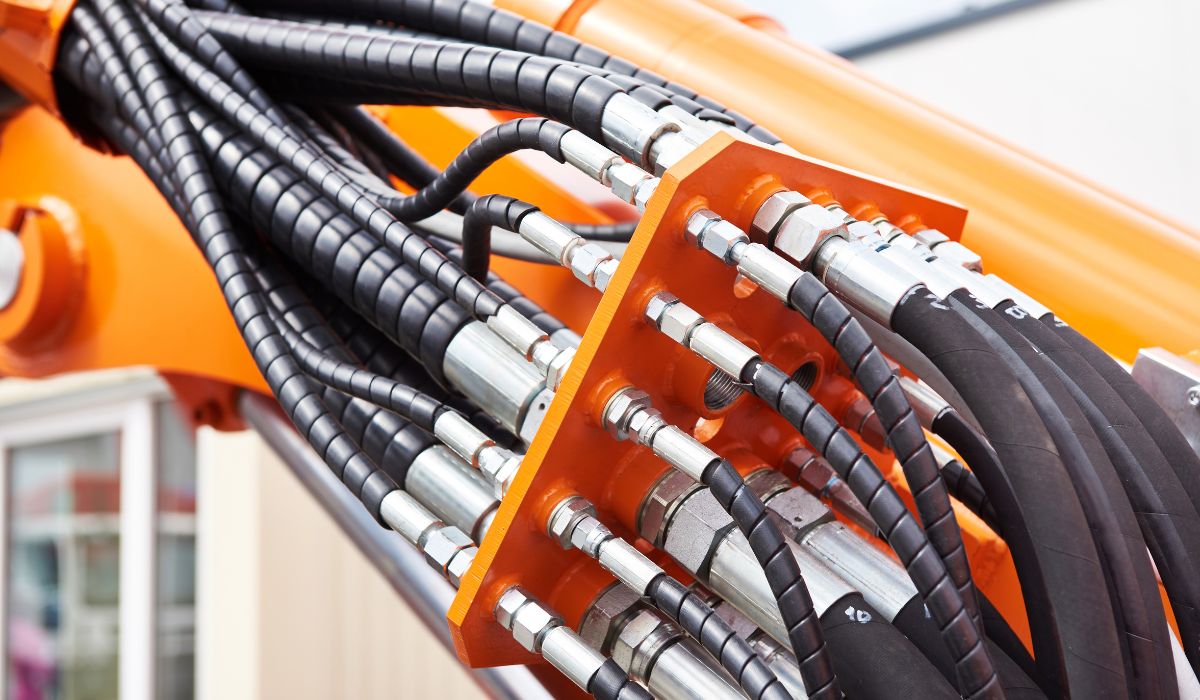

- Integration with PLCs and automation systems

- Improved safety and minimal manual intervention

Parc Robotics: Specialists in Custom Hydraulic Systems

At Parc Robotics, we focus on building hydraulic solutions that deliver:

- High accuracy and process consistency

- Long service life with minimal maintenance

- Quick changeover and easy integration

- Support for Industry 4.0 and smart monitoring

Whether you’re looking for a single hydraulic fixture or a complete automated setup, our team will design and build a solution tailored to your operation.

Our Key Hydraulic Solutions

- Hydraulic Clamping Fixtures

Ideal for securing parts in CNC machining, grinding, or drilling operations, especially when tight tolerances are required. - Hydraulic Welding Fixtures

These hold large components during complex welding operations. They are pressure-tested and designed for high structural stability. - Hydraulic Press Machines

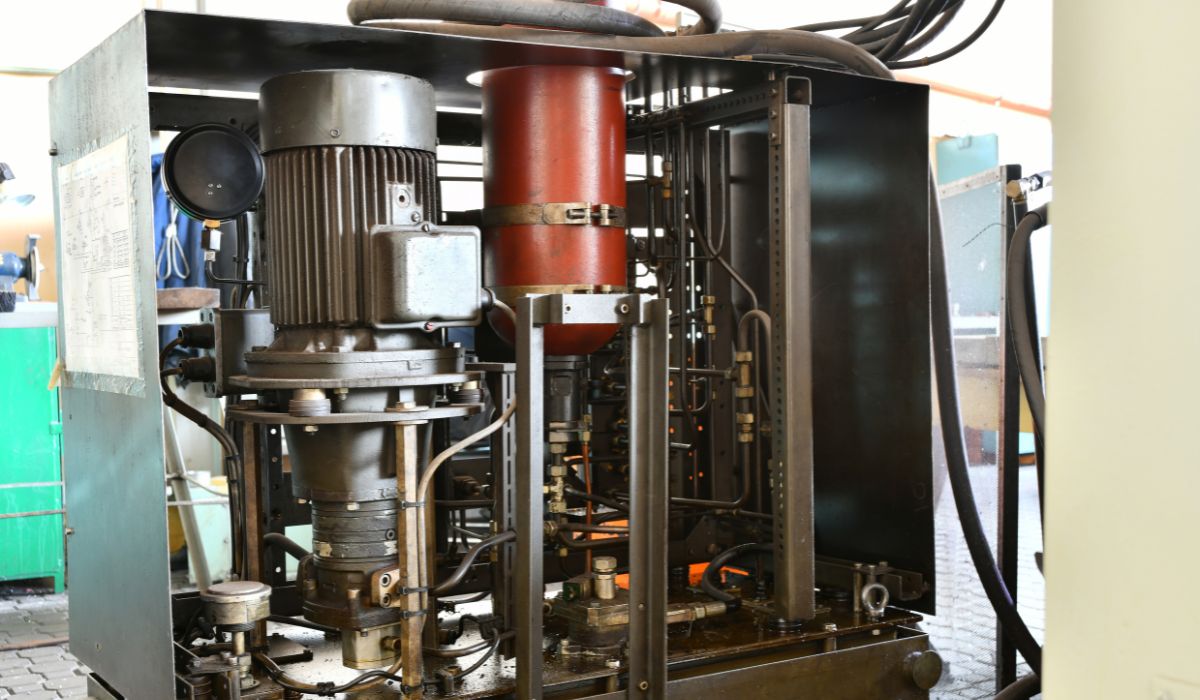

Custom-built presses for forming, trimming, and fitting tasks. Options include digital pressure regulation and operator-safe design. - Hydraulic Testing Benches

Designed for high-pressure leak testing, flow testing, and durability testing in automotive and aerospace applications. These are equipped with sensors, PLCs, and touchscreen HMIs.

Why Choose Hydraulic Over Manual or Pneumatic Fixtures?

Hydraulic systems offer unmatched clamping power and process control. They are best suited for applications that demand high precision, heavy-duty force, and high repeatability — especially in fast-paced manufacturing lines or where automation is a priority.

In comparison to manual or pneumatic systems, hydraulic fixtures:

- Handle higher loads

- Maintain repeatability across thousands of cycles

- Are more suitable for automated workflows

- Offer longer lifecycle and safety features

Industry Applications We Serve

Our hydraulic fixtures and machines are used across several industries, including:

- Automotive and commercial vehicle manufacturing

- Aerospace and defense component production

- Heavy fabrication and engineering

- Equipment assembly and hydraulic system suppliers

- Precision part machining and testing

Success Stories

Automotive Supplier – Pune

An automotive component manufacturer needed a solution for clamping multiple suspension parts during CNC machining. Parc Robotics designed a custom hydraulic fixture that reduced clamping time by 40% and increased output by 30%.

Aerospace Test Bench – India

We built a hydraulic testing bench for leak and burst pressure testing of aircraft fuel components. The system included safety cutoffs, digital control, and real-time pressure monitoring.

Our Design and Delivery Process

- Consultation and Planning

We start by analyzing your components, cycle times, space constraints, and automation needs. - Design Engineering

CAD models and hydraulic circuit designs are created based on specifications. Simulations are run to ensure performance and reliability. - Manufacturing and Assembly

Precision components are manufactured and assembled at our Pune facility. All systems undergo in-house testing. - On-site Setup and Support

We handle delivery, installation, and commissioning. Full training and documentation are included.

Why Choose Parc Robotics?

- Industry-specific expertise

- Fully customized solutions

- In-house design, manufacturing, and testing

- Integration with PLCs, sensors, HMIs, and automation software

- Reliable service and technical support

As a leading hydraulic fixtures and machine manufacturer, Parc Robotics offers complete support — from concept to commissioning.

Conclusion

Looking for a reliable hydraulic fixture and machine manufacturer? Partner with Parc Robotics for smart, scalable, and high-performance hydraulic systems.