Introduction: The Automotive Industry’s Transformation

The automotive manufacturing sector stands at a pivotal crossroads, where traditional methods intersect with cutting-edge technology. As global competition intensifies and consumer expectations soar, manufacturers face unprecedented challenges in maintaining quality while increasing production volumes.

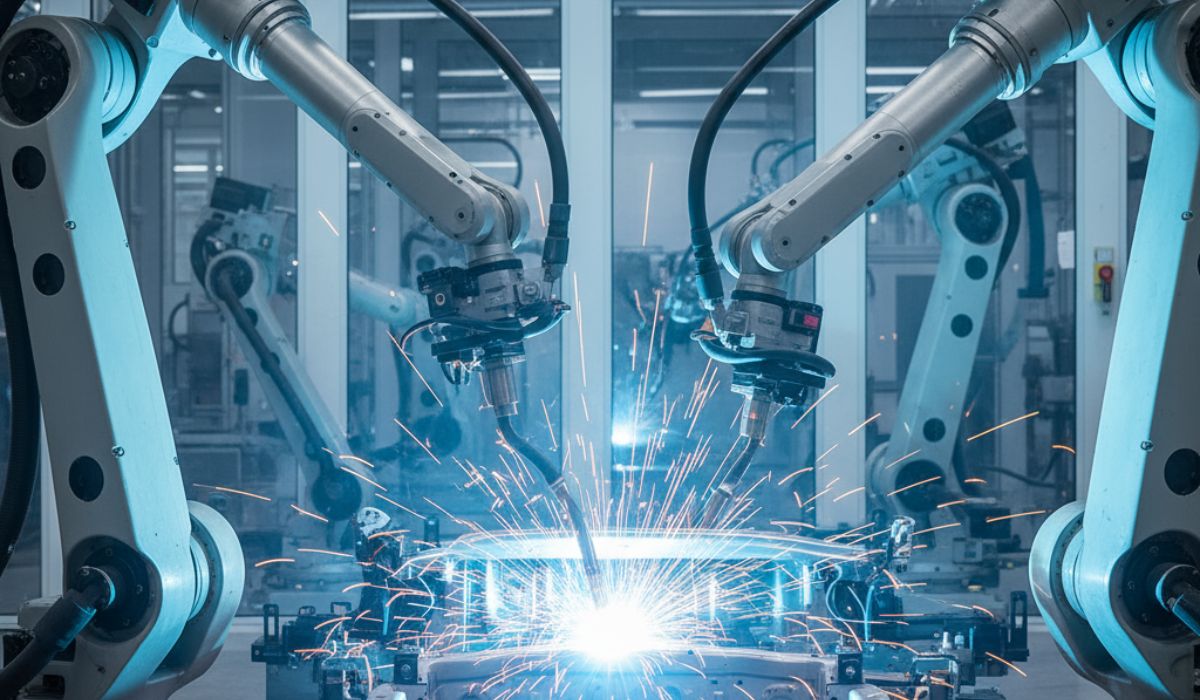

The welding segment, particularly crucial in automotive assembly, has emerged as a prime candidate for technological disruption. Industrial robotic welding for automotive parts represents more than just an upgrade—it signifies a fundamental shift in how vehicles are conceptualized, assembled, and perfected.

Across factory floors worldwide, manual welding stations are gradually giving way to sophisticated robotic cells where precision meets productivity. This transition isn’t merely about replacing human workers; it’s about enhancing human capabilities and creating synergistic relationships between skilled technicians and advanced machinery.

The automotive industry’s journey toward complete automation continues to accelerate, with robotic welding leading the charge in transforming production paradigms.

Understanding Industrial Robotic Welding Systems

Industrial robotic welding represents the pinnacle of manufacturing technology, combining mechanical engineering, computer programming, and advanced material science.

These systems typically comprise several key components: the robotic manipulator (arm), the welding power supply, the wire feeder, and the sophisticated controller that orchestrates every movement with microscopic precision.

What sets modern robotic welding apart is its intelligence quotient. Contemporary systems incorporate vision systems that can “see” and adapt to variations in part placement, machine learning algorithms that optimize welding parameters in real-time, and sophisticated sensors that monitor everything from arc stability to thermal dynamics.

This technological ecosystem enables the system to make split-second adjustments that would be impossible for even the most skilled human welder.

The evolution of these systems has been particularly remarkable in their democratization. Where once only automotive giants could afford such technology, today’s mid-sized manufacturers can implement robotic welding solutions through flexible financing models and modular systems that scale with business growth.

Advantages of Robotic Welding in Automotive Applications

Unmatched Precision and Quality Assurance

The automotive industry demands perfection, and robotic welding delivers exactly that. Every weld, from the smallest bracket to the critical structural component, maintains consistent penetration depth, bead geometry, and thermal profile.

This consistency translates directly to vehicle safety and longevity. Modern systems can maintain positional accuracy within 0.1 millimeters, ensuring that each automotive part meets exact design specifications.

Enhanced Production Throughput and Efficiency

Automotive manufacturing operates on tight schedules where every second counts. Robotic welding systems dramatically reduce cycle times while operating continuously through multiple shifts.

The elimination of human factors like fatigue, breaks, and variable working speeds creates a predictable, optimized production flow. Manufacturers implementing robotic welding typically report 40-60% improvements in overall equipment effectiveness (OEE).

Adaptability to Evolving Automotive Designs

The automotive industry’s shift toward electric vehicles and lightweight materials has created new welding challenges. Robotic systems demonstrate remarkable versatility in handling different materials—from traditional steels to advanced aluminum alloys and composite materials.

Quick-change tooling and digital reprogramming enable seamless transitions between different vehicle models and components.

Workplace Safety and Ergonomic Improvements

Welding environments present numerous hazards including toxic fumes, intense ultraviolet radiation, and ergonomic stressors. Robotic systems remove human operators from these direct dangers, creating safer working conditions.

Additionally, the consistency of robotic welding reduces the physical strain on quality inspectors and maintenance personnel.

Sustainable Manufacturing Benefits

Modern robotic welding systems contribute significantly to sustainability goals through optimized energy consumption, reduced material waste, and improved resource utilization. The precision of robotic welding minimizes consumable usage while the reduced rework rates lower the environmental footprint of manufacturing operations.

Key Applications in Automotive Manufacturing

The vehicle’s basic structure, known as the Body-in-White, requires hundreds of precise welds to create the foundation for all other components. Robotic welding systems handle everything from spot welding sheet metal panels to continuous arc welding of structural members.

The consistency achieved through robotic welding ensures crashworthiness and dimensional accuracy throughout the vehicle’s lifespan.

Chassis and Frame Manufacturing

As the backbone of any vehicle, the chassis demands absolute structural integrity. Robotic welding provides the repeatability needed for critical joints in ladder frames, unibody constructions, and specialized chassis for commercial vehicles.

The systems handle varying material thicknesses and complex joint configurations with equal proficiency.

Powertrain and Engine Component Welding

From transmission housings to engine blocks, powertrain components operate under extreme conditions requiring flawless welds. Robotic systems excel at welding cast iron, aluminum, and specialized alloys used in modern powertrains. The hermetic seals and structural welds in these applications leave no room for error.

Exhaust System Fabrication

The complex geometries of modern exhaust systems—including catalytic converters, mufflers, and piping—benefit immensely from robotic welding’s consistency. The systems handle the challenging combination of thin-walled tubing and varying material types while maintaining emission-control integrity.

Electric Vehicle Specific Applications

The electric vehicle revolution has created unique welding challenges, particularly in battery tray assembly and electric motor housing fabrication. Robotic welding ensures the integrity of battery enclosures while handling the specialized materials and precision requirements of EV components.

Types of Robotic Welding Systems in Automotive Manufacturing

Articulated Arm Robotic Welders

These versatile systems mimic human arm movement with multiple points of rotation, making them ideal for complex three-dimensional welding paths. Their flexibility makes them suitable for everything from small brackets to complete body assemblies.

Spot Welding Robots

Specifically designed for resistance spot welding, these robots excel at joining sheet metal components in automotive body shops. Their speed and precision make them indispensable in high-volume production environments.

Laser Welding Systems

Using concentrated laser energy, these systems provide exceptionally clean, precise welds with minimal heat distortion. They’re particularly valuable for visible joints and advanced materials where traditional welding might compromise aesthetics or material properties.

Collaborative Welding Robots

The latest innovation in automotive welding, collaborative robots work alongside human operators, combining robotic precision with human problem-solving abilities. These systems are perfect for low-volume, high-variability applications.

Implementation Strategy for Robotic Welding Systems

Comprehensive Process Analysis

Successful implementation begins with thorough analysis of existing welding processes. Manufacturers must identify bottleneck operations, quality pain points, and opportunities for standardization before selecting appropriate robotic solutions.

System Selection Criteria

Choosing the right robotic welding system involves evaluating multiple factors including production volumes, part variety, facility constraints, and future growth projections. The selection process must balance current needs with long-term manufacturing strategy.

Integration and Installation Planning

Seamless integration requires careful planning of facility layout, utility requirements, and material flow. Successful implementations consider everything from floor loading requirements to maintenance access points.

Workforce Development and Training

The human element remains crucial in robotic welding environments. Comprehensive training programs must address programming skills, maintenance procedures, troubleshooting techniques, and quality control methodologies.

Continuous Improvement Framework

Implementation represents just the beginning. World-class manufacturers establish metrics, monitoring systems, and improvement cycles to ensure their robotic welding operations continue to evolve and optimize over time.

Future Trends in Automotive Robotic Welding

Artificial Intelligence and Adaptive Control

Next-generation robotic welding systems incorporate AI algorithms that learn from every weld, continuously refining parameters for optimal results. These systems can detect and compensate for material variations, fit-up inconsistencies, and environmental factors without human intervention.

Digital Twin Technology

Virtual replicas of robotic welding cells enable manufacturers to simulate, optimize, and validate welding processes before physical implementation. This digital approach reduces commissioning time and ensures optimal performance from day one.

Advanced Sensing and Monitoring

Sophisticated sensor systems now provide real-time analysis of arc characteristics, molten pool behavior, and thermal management. This data-driven approach enables predictive quality control and prevents defects before they occur.

Sustainable Welding Solutions

The industry’s focus on sustainability drives development of energy-efficient robotic systems that minimize environmental impact through reduced power consumption, optimized material usage, and longer equipment lifespans.

Hybrid Manufacturing Approaches

Combining additive manufacturing with robotic welding creates new possibilities for repair, modification, and custom component fabrication. This integrated approach particularly benefits low-volume and specialty vehicle production.

Frequently Asked Questions

What makes robotic welding particularly suitable for automotive applications?

Automotive manufacturing demands high volumes, consistent quality, and strict adherence to safety standards—all areas where robotic welding excels. The technology’s precision, repeatability, and efficiency align perfectly with automotive production requirements across all vehicle segments.

How does robotic welding handle different automotive materials?

Modern robotic welding systems incorporate sophisticated sensing and control systems that automatically adjust parameters for different materials. Whether working with advanced high-strength steels, aluminum alloys, or specialized composites, the systems maintain optimal welding conditions through real-time monitoring and adjustment.

What technical expertise is required to operate robotic welding systems?

While robotic systems simplify many aspects of welding, they require skilled technicians proficient in programming, maintenance, and quality assurance. Most manufacturers implement comprehensive training programs to upskill their workforce, combining equipment-specific knowledge with fundamental robotics principles.

Can robotic welding systems adapt to design changes in automotive components?

Absolutely. The digital nature of robotic welding makes adaptation to design changes remarkably efficient. Programming modifications can be implemented quickly, and many modern systems can even automatically adjust to minor variations in component fit-up through advanced sensing technology.

What quality assurance measures are integrated into robotic welding systems?

Contemporary systems incorporate multiple layers of quality monitoring including real-time parameter tracking, vision-based inspection systems, and data analytics that predict potential quality issues before they occur. This comprehensive approach ensures consistent output and simplifies compliance with automotive quality standards.

How do robotic welding systems impact workforce requirements in automotive plants?

While robotic systems reduce the need for manual welders, they create demand for higher-skilled positions in programming, maintenance, and system optimization. The technology typically leads to workforce transformation rather than reduction, with employees moving to more technically sophisticated roles.

What maintenance considerations are unique to robotic welding systems?

Preventive maintenance focuses on regular calibration, consumable replacement, and system diagnostics. Unlike manual welding equipment, robotic systems provide detailed maintenance alerts and performance analytics that enable predictive maintenance strategies, minimizing unplanned downtime.

Conclusion: The Future is Automated

The integration of industrial robotic welding for automotive parts represents more than just technological progress—it signifies the automotive industry’s commitment to excellence, safety, and innovation. As vehicles become more complex and consumer expectations continue to rise, robotic welding provides the foundation for manufacturing excellence.

The journey toward fully automated manufacturing continues to accelerate, with robotic welding at the forefront of this transformation. Manufacturers who embrace this technology today position themselves not just for current success, but for leadership in the automotive industry of tomorrow.

The precision, efficiency, and flexibility of robotic welding make it an indispensable tool in creating the next generation of vehicles that will transport us into a smarter, safer automotive future.