Engineering-Driven Robotic Automation for Two Wheeler Frame Production Two wheeler frame automation requires more than standard welding robotics—it demands an integrated approach to part positioning, thermal management, and process control. Parc Robotics designs and deploys fully engineered robotic welding systems specifically…

Gantry Automation System in India

Indian manufacturing is shifting toward high-precision, high-throughput automation. For applications involving heavy payloads, long travel distances, and structured linear motion, a Gantry Automation System provides superior rigidity, repeatability, and scalability compared to conventional robotic arms. Parc Robotics engineers and integrates industrial…

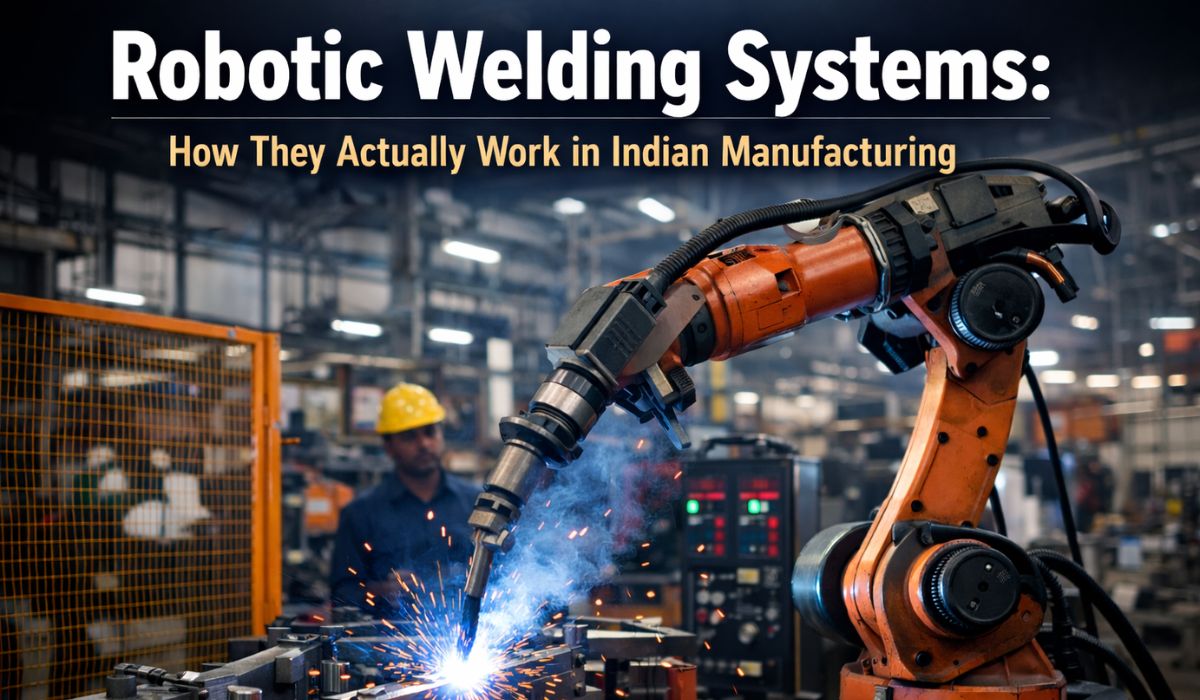

Robotic Welding Systems: How They Actually Work in Indian Manufacturing

For manufacturing engineers, production managers, and plant heads across India, robotic welding presents a compelling proposition. It promises higher throughput, consistent quality, and reduced dependency on skilled welders. However, the journey from procurement to profitable operation is often misconstrued. The common…

Robotic Automation Solutions in Manufacturing: How Indian Industries Are Moving from Manual to Smart Automation

Indian manufacturing stands at a historic inflection point, and the adoption of Robotic Automation Solutions in Manufacturing is the defining response. For decades, the sector’s competitive advantage was predicated on abundant, cost-effective labor. Today, that model is under severe strain. Rising wage expectations,…

Robot Is Not the Solution: Automation Problems That Robots Alone Can’t Fix

Industrial automation is often misunderstood as a hardware problem. In many factories, automation discussions begin with robot brands, axis speed, payload capacity, and reach. The assumption is simple: if the robot is powerful and precise enough, the automation project will succeed….

Future of Robotics and Automation in Indian Manufacturing

Indian manufacturing is standing at a critical turning point. For decades, growth depended on low-cost labor and incremental capacity expansion. That model is breaking down. Rising wages, inconsistent skill availability, tighter quality standards, and global competition are forcing Indian manufacturers to…

Robotic Welding Fixtures: How Automated Fixturing Improves Weld Consistency

As manufacturing shifts toward automation, robotic welding systems are increasingly used across automotive, fabrication, and heavy engineering sectors. While robots receive most of the attention, the accuracy and repeatability of any automated welding process depend heavily on the fixturing used to…

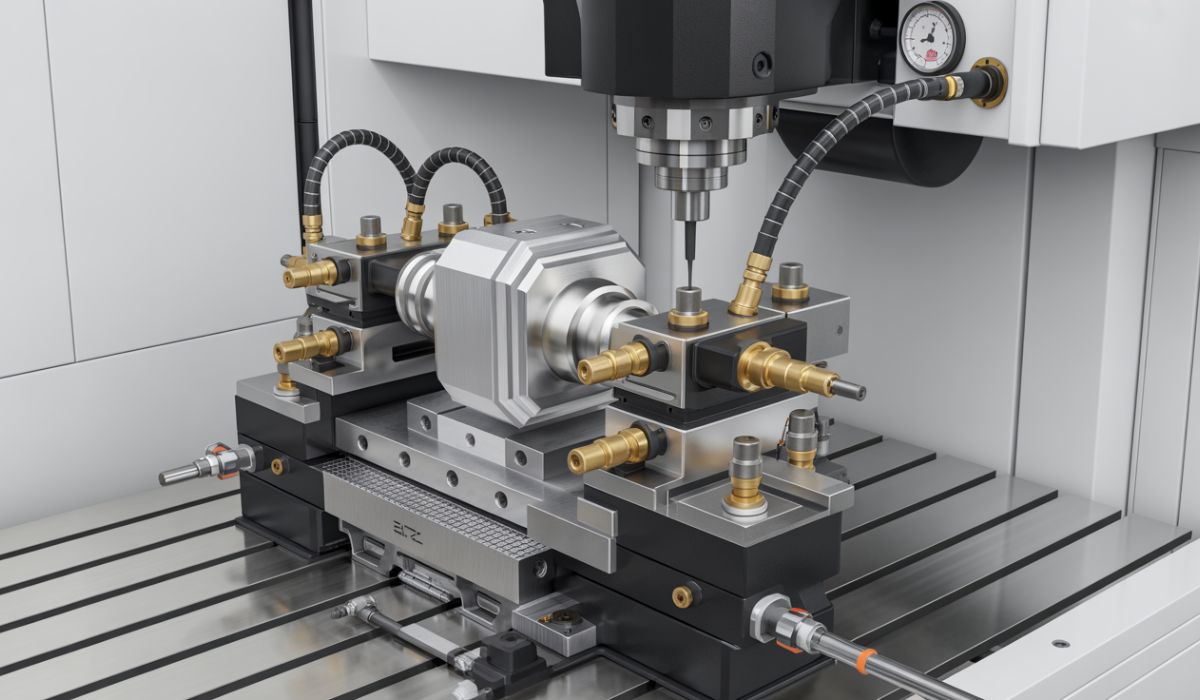

Hydraulic Fixtures for CNC Machining: Design Logic, Accuracy, and Production Reliability

In CNC machining, fixture design is not a support function. It is a process-defining element. Tool accuracy, surface finish, cycle time stability, and even tool life are directly influenced by how consistently a component is located and clamped. Hydraulic fixtures exist…

Automated Assembly Line Solutions for Automotive & Electronics Manufacturing

Automotive and electronics manufacturers today face harsh operational realities: rising labour costs, unpredictable workforce availability, and unacceptable quality variation. When margins depend on consistency and speed, manual assembly lines collapse under pressure.The only sustainable path forward is assembly line automation —…

Why SPM Manufacturing Is Becoming Critical for Indian Automotive Productivity

Why SPM Manufacturing Topic Matters Now Let’s get one thing clear from the start — Indian automotive productivity is hitting a ceiling, and the bottleneck is NOT manpower, NOT machines, and NOT raw material. The real bottleneck is process inconsistency. Plants…