Introduction

Body-in-White (BIW) plays a crucial role in automotive manufacturing, ensuring structural integrity, safety, and efficiency. Pune, being a hub for industrial and automotive manufacturing, is home to some of the leading BIW projects and automation solutions providers in India.

If you’re looking for custom BIW automation solutions, this guide will help you explore the best providers, their expertise, and what to consider when choosing the right partner.

What is BIW in Automotive Manufacturing?

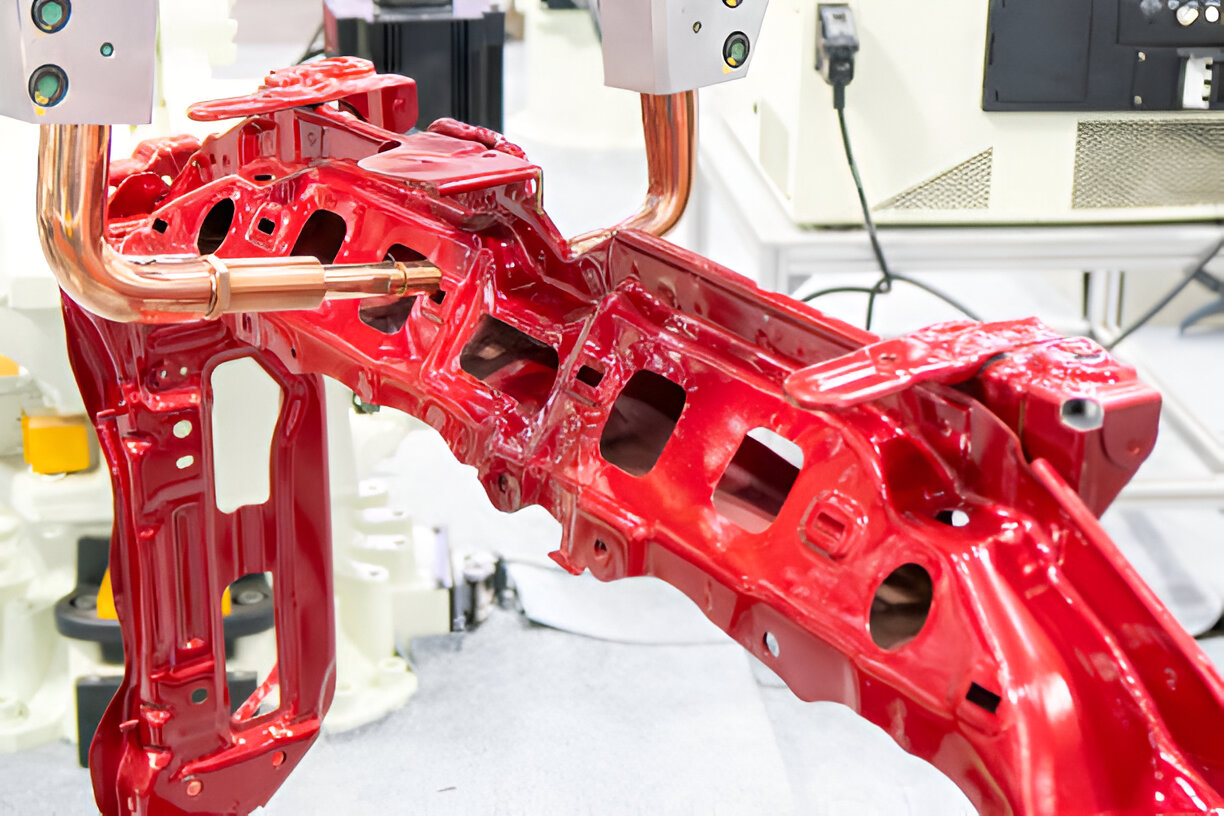

Body-in-White (BIW) refers to the stage in automobile manufacturing where the vehicle’s body frame is assembled before painting and final assembly. BIW includes: Spot welding & robotic welding fixtures.

- Heavy fabrication & structural assembly.

- Battery assembly line integration for EVs.

- Hydraulic & automation fixtures for precision engineering.

Automakers rely on advanced BIW design and automation for high-quality, lightweight, and durable vehicle structures.

Key Aspects of BIW Manufacturing

BIW manufacturing involves advanced technologies and precision engineering to ensure the structural integrity of vehicles. Key aspects include:

- Robotic welding automation for accuracy and efficiency.

- Spot welding lines and custom assembly fixtures.

- Heavy fabrication solutions for durability.

- Battery assembly line integration for electric vehicles.

- Hydraulic and automation fixtures to streamline production.

How to Select the Right BIW Manufacturing Partner?

Choosing the right BIW projects solutions provider requires careful evaluation. Consider the following: Industry Experience – Look for expertise in automotive BIW design.

- Automation & Technology – Advanced robotic welding and automation enhance efficiency.

- Customization – Ensure the provider offers tailored BIW solutions.

- Support & Maintenance – Reliable after-sales support for smooth operations.

- Scalability – Choose a partner capable of handling large-scale projects.

One-Stop Solution for BIW & Automation Needs

Pune’s leading automation solution providers offer: Complete BIW assembly line design & automation.

- Robotic welding, spot welding, and heavy fabrication solutions.

- Integration of battery assembly lines for EV production.

- Hydraulic fixtures & precision engineering.

By selecting the right BIW solutions provider, automotive manufacturers can achieve faster production, superior quality, and cost-efficiency.

Final Thoughts

Pune is at the forefront of BIW projects design & manufacturing, with top-tier companies offering robotic automation, welding fixtures, and turnkey automotive solutions. Partnering with an experienced BIW automation provider ensures high-performance vehicle structures and production efficiency.

FAQs

Q1. What is BIW in automotive manufacturing?

BIW (Body in White) refers to the car body structure before painting and assembling.

Q2. Which are the best BIW project solutions providers in India?

Some of the top BIW solutions providers in India include XYZ Automotive, ABC Engineering, and Tech Solutions.

Q3. What are the key processes in BIW manufacturing?

The key BIW manufacturing processes include spot welding, laser welding, hemming, riveting, and structural assembly.

Q4. Why is BIW design important for the automotive industry?

BIW design determines the car’s safety, weight, and durability, which impact overall performance and efficiency.