In the past, many manufacturers saw automation as a “nice to have” addition to their operations. It was mainly used to improve productivity, quality, and reduce costs. However, over time, things have changed. Today, automation is no longer just a luxury—it’s essential for businesses that want to stay competitive in the market.

With the challenges of labor shortages and growing demands for better quality, manufacturers can’t afford to ignore automation. Luckily, technology has evolved too. Today, automation is much more accessible and affordable, even for smaller manufacturers who once thought it was out of their reach.

In this guide, let’s explore manufacturing automation, its benefits, how to get started, and some key technologies you should know about.

What is Manufacturing Automation?

Manufacturing automation, also known as industrial automation, is all about using technology, machines, and systems to make production processes more efficient. The main goal is to reduce reliance on manual labor and improve overall performance in the factory.

Automation can include various areas like:

- 3D design: Creating digital models for machines, robots, and equipment.

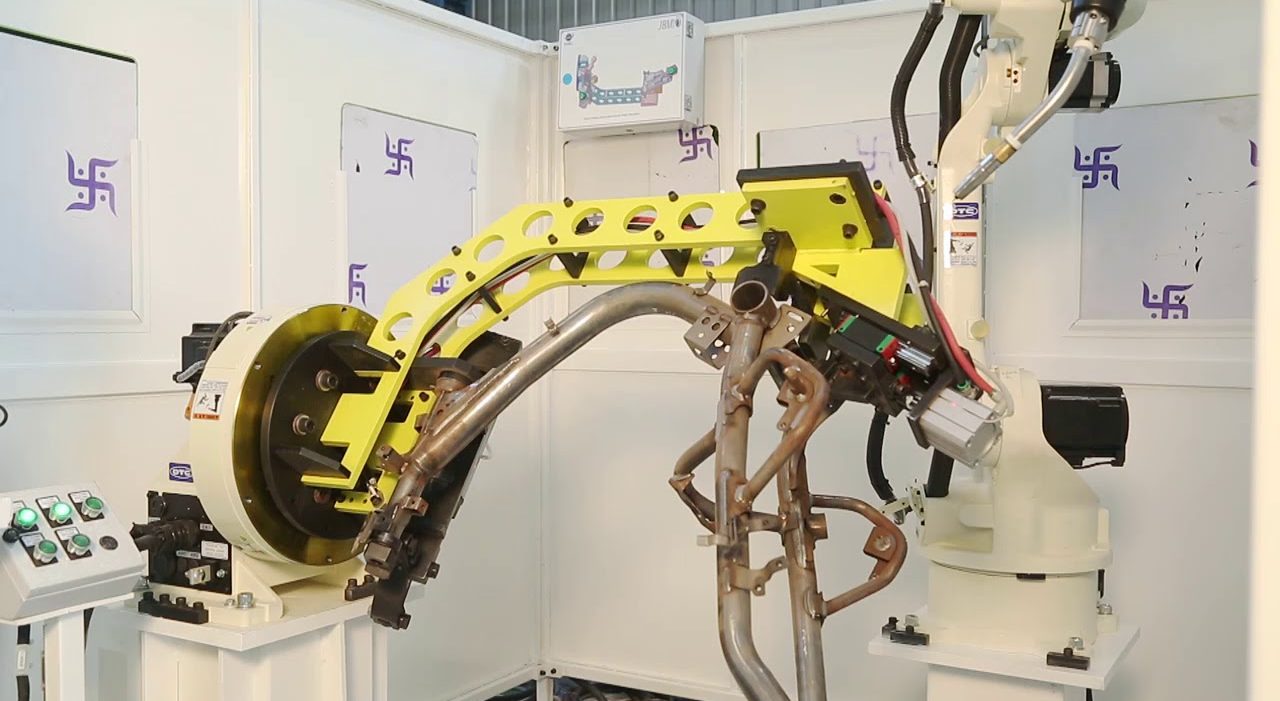

- Robotics: Using robots to do tasks like packaging, assembly, and welding.

- Programming: Writing code to control machines and automate processes.

- AI & Machine Learning: Using smart systems to improve efficiency, predict issues, and control quality.

- Remote monitoring: Tracking performance and machine health in real time with sensors and cameras.

Automation can range from simple tasks like moving a box to more complex processes like automating entire production lines.

Suggested Content: Check About Robotic Systems

Why Should You Consider Automation?

The manufacturing world is changing. With rising labor costs and labor shortages, as well as the demand for better quality, now is the time to consider automation. Automation helps in many ways:

- Boosts productivity: Machines work around the clock without breaks, improving overall production.

- Improves quality: Automation reduces human error, leading to more consistent and precise work.

- Cuts costs: Machines can do repetitive, labor-heavy tasks more efficiently, saving both time and money.

- Reduces lead times: Products get from order to delivery faster, which is great for customer satisfaction.

- Improves safety: Dangerous or physically demanding tasks can be automated, keeping workers safe.

- Tackles labor shortages: Automation helps keep production running smoothly, even when it’s hard to find skilled workers.

- Increases employee retention: By automating the repetitive work, employees can focus on more meaningful tasks, improving job satisfaction.

Types of Manufacturing Automation

There are two main types of automation you’ll come across: Fixed automation and Flexible automation.

- Fixed Automation: This type is for high-volume production. The machines are set up to do one specific task and can’t be changed easily. For example, a machine that fills ice cream cups is fixed automation—it can only fill cups, not do other tasks.

- Flexible Automation: Here, machines can be reprogrammed to handle different tasks. This type of automation is more adaptable to changing needs. For example, collaborative robots (cobots) can perform various tasks and are easily reprogrammed.

Which Industries Use Automation?

Automation is transforming industries around the world. Some key sectors that benefit from automation include:

- Pharmaceutical manufacturing: Automation helps with tasks like dispensing, sample preparation, and quality control. It speeds up production while maintaining accuracy.

- Automotive manufacturing: Robots handle tasks like assembly and welding, making the process faster and more precise.

- Aerospace manufacturing: Robots assist in assembling large components like wings and fuselages, ensuring high accuracy and safety.

- Food processing: Automation handles tasks like sorting, cutting, and packaging food, improving quality and speed.

How Robots Help in Manufacturing Automation

Robots play a major role in manufacturing automation. They’re used to performing repetitive tasks that humans usually do, but they do it faster and more accurately.

- Collaborative robots (cobots): These robots work alongside humans. They’re safe, easy to program, and can perform multiple tasks. Cobots are ideal for smaller businesses that need flexibility.

- Industrial robots: These robots are designed for heavy-duty tasks like welding and painting. They are faster and more precise but need to operate in safe areas away from humans.

- Gantry robots: These robots work on a large scale and are great for tasks like material handling and assembly. They can carry heavier loads and work across a bigger area.

How to Start With Manufacturing Automation

Getting started with automation might seem overwhelming, but it’s easier than you think. Here are some simple steps to kick things off:

- Set clear goals: Know what you want to achieve with automation—whether it’s improving quality, reducing costs, or increasing production speed.

- Start small: Begin with simpler tasks to test the waters. Once you’re comfortable, you can scale up.

- Get support: Make sure management is on board with your automation plan. You’ll also need a dedicated team to handle the project.

- Choose the right processes to automate: Not all tasks need automation. Look for processes that are repetitive, time-consuming, or difficult for human workers.

Building an Advanced Manufacturing Team

As you dive into automation, it’s helpful to form a dedicated team within your company. This team will focus on implementing automation across your operations. Having a team with the right skills can help speed up the process and ensure success.

The Automation Workflow

There are four main stages in any automation project:

- Design: Start by creating a design for the automated system. Tools like 3D design software can help you visualize and plan the setup.

- Automate: Once the design is ready, you can program the machines and robots to perform tasks automatically.

- Deploy: After testing, deploy the automation system in your factory.

- Operate: Monitor the system regularly to ensure it’s working efficiently and make adjustments as needed.

The Role of AI in Automation

AI is transforming the way automation works. It helps in several ways, such as:

- Smarter programming: AI can help robots understand tasks better and work more efficiently.

- Real-time adjustments: AI can change a robot’s actions based on real-time data, making them more adaptable.

- Improved design: AI can help create better designs for robots and systems, making automation more effective.

What Are the Risks of Manufacturing Automation?

While automation has many benefits, there are also some risks to consider, like technology risks (where the system doesn’t work as planned) and process risks (where the system doesn’t perform consistently). However, new technologies like digital twins and AI are making it easier to manage these risks.

The Future of Manufacturing Automation

The future of manufacturing automation is bright. It’s expected to grow rapidly in the coming years, with more industries adopting automation to improve their operations. AI, robotics, and new technologies will continue to make automation smarter, safer, and more accessible to manufacturers of all sizes.

In conclusion, automation is no longer an optional extra—it’s a necessity for manufacturers who want to stay competitive. By embracing automation, manufacturers can increase productivity, reduce costs, and meet the growing demand for quality products. And with technologies becoming more affordable and easy to implement, now is the perfect time to get started!